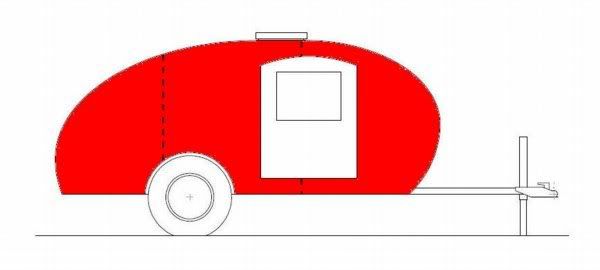

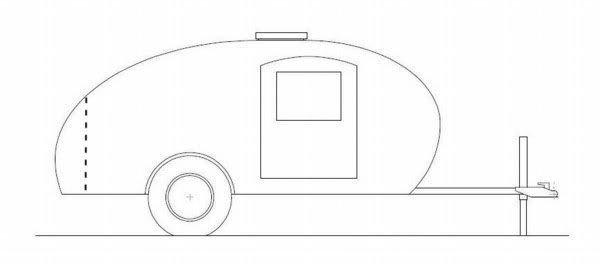

If I do the sides in 4x red, I will have two seams...one through the door area and one around the galley hinge area.

If I do the sides in 5x white (and the roof in red) then I will have only one seam on the side about 1 foot from the rear, not too noticeable.

But then I will have more seams on the roof because of the 4x red (my tear is 5’ wide). But I figure seams on the roof are less noticeable than on the sides. This is the dilemma that I have been tossing in my mind for the past several days and I don't know how I will proceed. Heck, I still may paint the darn thing.

To make a long story short (and to get to the point of this thread), if I do go the aluminum route, how do I do the seams for maximum sealage (is that a word?) but also to make it as less conspicuous as possible.

I've seen the thread on riveting and screwing (pic above) but can the edges be overlapped and glued without the screws? I'd like as smooth of a finish as possible but I don’t want the seams popping loose down the line.

Any suggestions, ideas or input (positive or negative) will be welcomed. I hope I have made myself clear.

Mark (& Cindi)

Mark (& Cindi)