Hi all,

I was doing some sketches last night and had a question about the wiring of the TD. I will be having a few lights spread out throughout the cabin and then some porch lights. My question is this, I have never daisy chained anything when doing wiring for speakers or data networks, its always been a no no for me. I could have sworn I saw somewhere on the site where people are daisy chaining their lights and not doing what I call “home runs” for every light. Is there some good reason to daisy chain other than your TD lights going out not being the end of the world?

TIA,

R

Wiring for lights

24 posts

• Page 1 of 2 • 1, 2

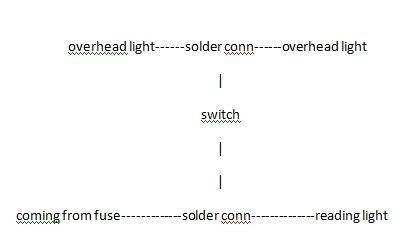

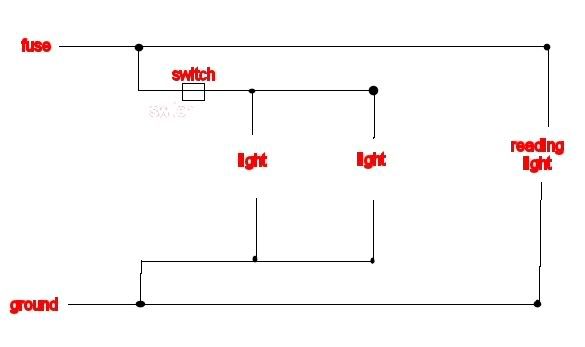

As long as the total amp draw of all of your lights doesn't exceed the rating for the choice of wire, there is no reason to not run multiple lights from one run of wire. In wiring my TD, where I have made connections to the main wire, I have soldered the connections and then covered that with liquid electrical tape.

Jeff & Micki

53 F100

Mercedes turbo diesel

Teardrop "finished" as if they ever are

You can never be lost if you don't care where you are going!

53 F100

Mercedes turbo diesel

Teardrop "finished" as if they ever are

You can never be lost if you don't care where you are going!

-

mechmagcn - Donating Member

- Posts: 813

- Images: 56

- Joined: Mon May 05, 2008 9:47 pm

- Location: Moro Bay, AR