Today's scheduled work went really quickly 1 1/2 hours work - 4 beers.

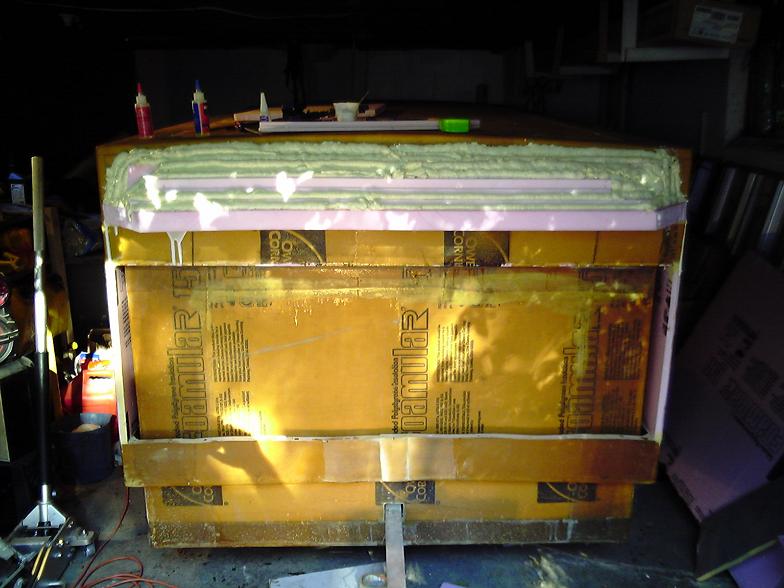

misc. foam scraps were glued into place using a 50/50 mix of 5 minute epoxy and glass micro balloons (the mixture which henceforth shall be referred to as "wet micro").

Exactly one can of spray in expanding foam insulation was sprayed into place, and began expanding.

The next morning, things were a lot more expanded than in these pictures, but the lighting wasn't good enough for a pic.

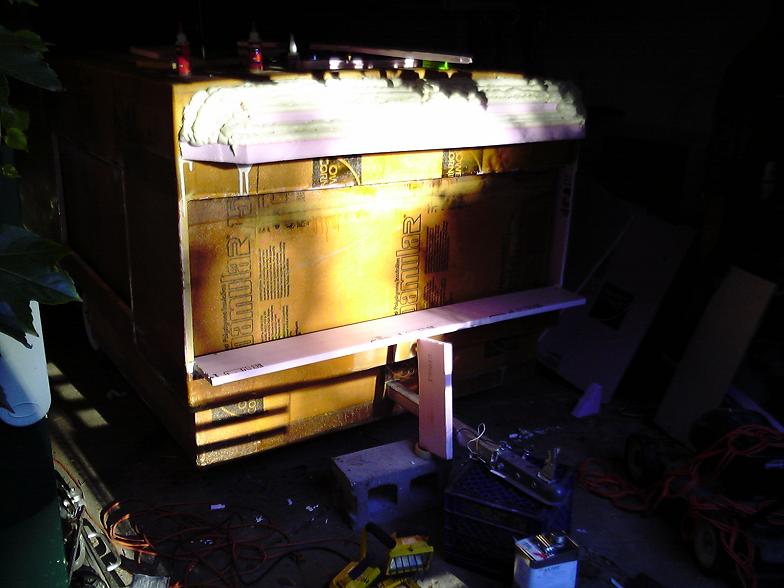

The next step was to start on the bottom portion of the fairing. A piece of 1" thick foam was wet microed into place extending 6" forward of the front wall of the trailer. this will give me a 7" deep shelf at the head of the bed when the sides and window are in place, and should also give me enough room to hang curtains/blinds/window shade/whatever without having to remove them when i lower the top.

I'm making a slight design change. Originally, when the top was lowered, the lower edge of the top was even with the lower edge of the trailer deck. This required a seven inch tall gap to be cut into the cap so that it can be lowered around the tongue. I've now decided to not lower the top completely for towing. It will stop 2" short of the bottom of the camper. This will do 2 things for me. The tongue gap can be reduced to only 3" by 5", which is pretty easy to do structurally, and shouldn't require any gap filling when the top is raised.

Secondly: with a ground clearance of only 8", i am a little worried about the lower edge of the cap having to absorb the full force of a frontal impact with the ground when hitting a pothole while navigating a steep driveway (it could happen). If the top isn't completely lowered, the camper deck will be the thing that makes contact with the ground, and that is so tough that i'm not worried in the least about it. I have some kevlar cloth that i'm going to epoxy into place on the leading edge of the deck just like the fiberglass cloth. This stuff is used by kayakers to prevent abrasions to their boats when they come into contact with boulders, so i think it will be good enough for my purposes. remember also that this camper is going to act as a kind of base camp while canoeing, so it's going to scrape along a lot of submerged rocks while floating down the river.

slyeager

Teardrop Inspector

Sure would be cool if you could somehow dispense beer cans/bottles through that hole........lol

funny story: my brother in law made a similar remark when he was helping me carry in several hundred pounds of ceramic tile to install around my new bathtub/2 person hot tub. "sure would be cool if you installed a T.V. into the wall at the foot of the tub and had a few hundred watts of surround sound in there."

3 weeks and $1,100 later, there was a 14" LCD flat screen TV recessed into the wall behind the tile, and a pair of custom fiberglass speaker enclosures in the tub (only 200 watts of stereo sound though).

The moral of this story: Be careful what you say around me. If the idea is crazy/strange/cool enough, i might have to do it as a matter of pride, no matter what the cost or time spent.

Two questions, if I may?

1. What do you estimate will the weight of the completed trailer be?

2. How are you going to finish it off, i.e. are you going to paint it, or shoot it with gel coat?

The weight, fully outfitted with a queen sized futon, air conditioning, refrigerator,heater, microwave oven, and 2 group 31 AGM batteries to run it all is..... wait for it....... 750 pounds.

the bare camper, not outfitted, but tow-able, and water tight is only going to weigh about 350 pounds. I actually could have built this a lot lighter if i had only understood at the beginning of this project, exactly how strong and rigid foam cored fiberglass construction really is. I could have lost about a hundred pounds of wooden deck framing and plywood flooring without making the BUB any less durable.

As far as an exterior coating goes, i'm going to smooth out the surface by applying a layer of wet micro, sanding everything flat and smooth, and then painting in the same fashion that you paint a car. I'm not sure whether i'm going to do the painting myself, or drag the bub to an auto body shop.

The one limiting factor i have in painting is color and it's associated temperature when exposed to sunlight. Any dark colors convert enough of the sunlight to heat, that the foam will begin to shrivel and pull away from the fiberglass. This really starts to happen at about 200 degrees F but i want to take no chances, and am planning on a white camper with some small colored accents. Any creative ideas with colors and patterns would be appreciated.

[/img]

[/img]