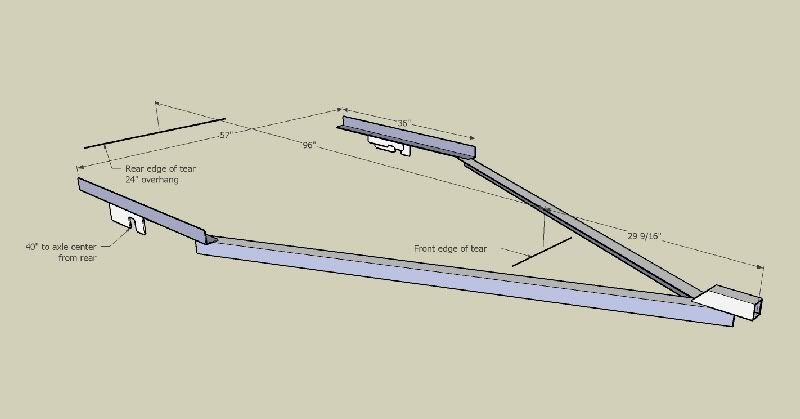

tinksdad wrote:I'm looking at this axle for an ultralight....

It says 57 inch frame width (usually measured to outside of brackets), so that would probably suit a 60" body if you used, say, 4"x4" angle under the body sides instead of the 2"x2" shown in those plans.

The height of this axle should be OK, though not ideal - it's got a 30 deg down start angle and it says the brackets are 1 inch above the tube (though they look a lot more than that in the photo).

Based on the Reliable web site for this axle (

http://www.reliabletool.com/products/r1000lb.htm) it will be around 4" from the spindle up to the top of the axle bracket under load. So with a 14" wheel (about 12.5" static radius), that will be around 16-17" from the ground to the top of the axle bracket which is quite workable.

One feature of this ultralight chassis is that it only has the thickness of the side angle (1/8") between the axle bracket and the body, where most trailers have a 2" tube between the two, so the ultralight rides lower than most chassis.

Andrew