thank you all for the words of encouragement...it's a hell of allot more fun to build this with all of you cheering on! i especially like the

italics reference, tom...it does have the same feel.

steve, i'm considering a lap-joint or a butt-joint with biscuits...haven't made up my mind. i don't want the seam to show, inside or out, so i'll decide when i figure out how wide the door frames will be. but i am leaning towards the lap-joint.

chris, i'd be happy to have you over. i'm almost always a laid-back, calm dude, but when i'm woodworking i can get pretty intense. as long as you don't mind loud classic rock, a beer or two, and the occasional weaving of a tapestry of cuss words when i goof, you're more than welcome. i should get heavy into the construction in two weekends.

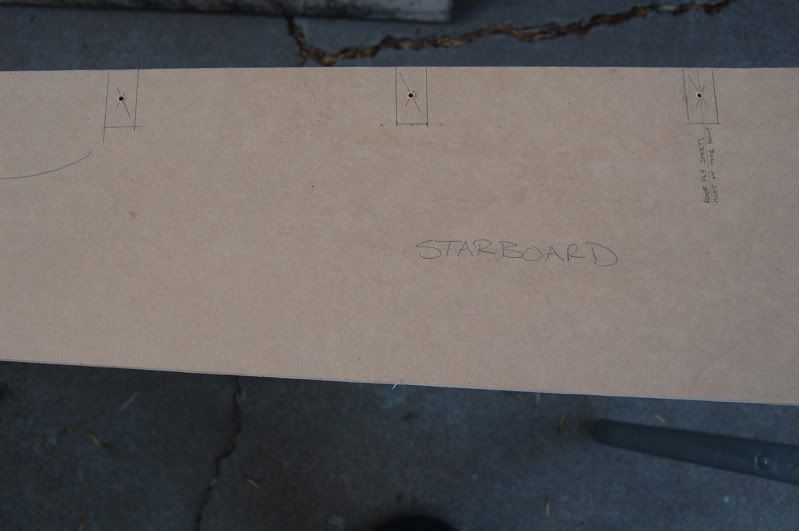

today i cut a template from 1/2" MDF. i decided that it would be easier to cut identical profiles if i used a template and a flush-trim router bit. add to that the fact that i want to build an aluminum-skinned TD after i build this woody and the logic behind making a template makes more sense. i hope i'm headed down the right path.

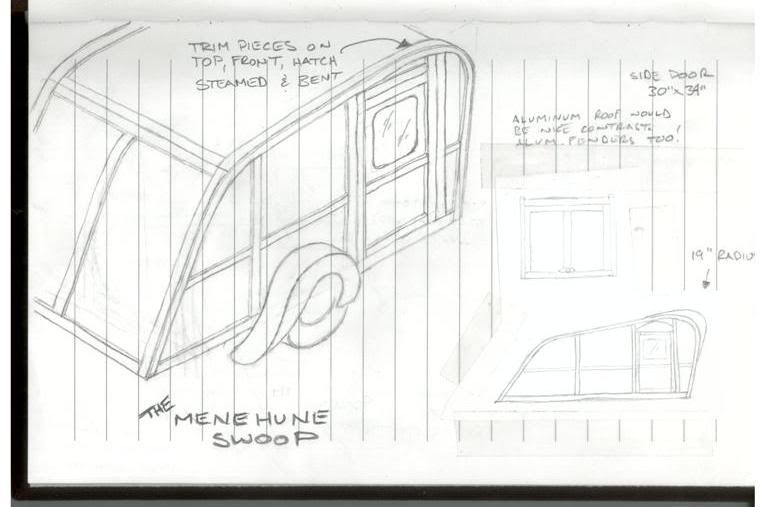

i experimented with the top aft edge. i'm on the fence - i can't decide if i like or dislike the upward swoop. i can easily round off the edge to a more traditional profile if i decide i don't like it after mulling it over for a while.

BTW, we had thunderstorms in L.A. today so i had to work under the patio cover. there you have it...proof that it does indeed rain in SoCal!

-miguel

Very cool! You have officially contracted TD fever. Keep us posted on the progress.

Very cool! You have officially contracted TD fever. Keep us posted on the progress.

I can't start yet, but I do finally have a profile sketched out that I like...

I can't start yet, but I do finally have a profile sketched out that I like...

.

.