Determining Axle Length?

21 posts

• Page 1 of 2 • 1, 2

Determining Axle Length?

So, if I wanted to build a basic 4 x 8 TD, and wanted to use a torsion axle, how would I determine axle length?

Uncle Chan

-

Uncle Chan - Teardrop Master

- Posts: 191

- Images: 12

- Joined: Sat Feb 21, 2009 6:02 pm

- Location: Rosalia, WA

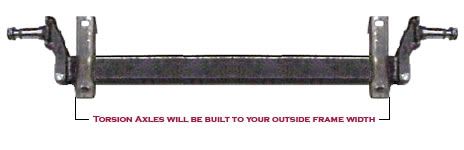

I figured it out. If I use a torsion axle, I will want the width of the axle to be the same as the outside frame width. So, a 48 inch wide frame would need a 48 inch torsion axle.

Uncle Chan

-

Uncle Chan - Teardrop Master

- Posts: 191

- Images: 12

- Joined: Sat Feb 21, 2009 6:02 pm

- Location: Rosalia, WA