My hinge spacers are probably a 16th too tall maybe?

Also the door looks "funny" because it doesn't sit all the way in the door jamb anymore, I don't remember seeing this before, even with people who had just plywood walls and doors.

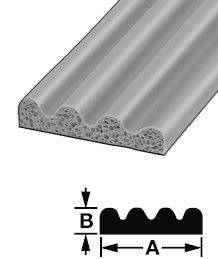

I thought about putting seals on the door jamb but this defies logic to me because when the door closes it is naturally going to want to pull up the seal. I mean you have to get it tight enough to seal, but loose enough for the door to slip over it which seems amazing to me, but maybe that's the way it is. I tossed one up there to see:

I've seen people make a inner door frame and that may be what I am needing to do to take up the extra space and to make it seal, I just don't know at this point because I have seen it without them too like on this Kit:

Flush doors and no inner frame, and the door sits flat with the wall... What gives... I want this!

Can you guys post your seals and how they are oriented? I know there are a hundred ways to do it but how are you t molding and other guys with outer frames doing yours? I want to know exactly what I am going to be doing before I bust all my door jamb trim off and start making my door jambs bigger! Thanks...

Mark (& Cindi)

Mark (& Cindi)