Thanks all for your nice comments.

Progress has been slow. Before the monsoon hit this weekend, my wife helped me pull the teardrop off the trailer to flip it over. I had some work to do on the belly side and thought it would be easier to do the work "bottoms up."

First, I needed to work on the front and rear roll pans. I had thought about making them from plywood and foam, but the trailer sides only extend 2" below the floor. So I added wood filler strips and planed and sanded them to match the front and rear radius.

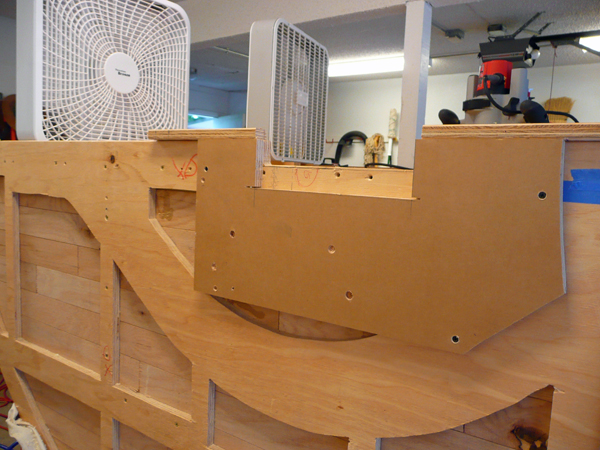

Next the sidewalls were notched to provide extra clearance for the axle's torsion arms. (From the way I ordered my axle, I only had about 1/4" clearance from torsion arm to the sidewall and didn't think that would be enough.) So I cut out that portion of the sidewall below the floor and rabbeted 1/2" into the 3/4" plywood "framing." The picture shows the template I cut for using my router with a pattern bit.

I plan to epoxy the sidewall extensions and edges of the plywood framing. (My floor already has 3 coats of CPES on it.) After the epoxy is cured, I'll add a coat or two of rubberized undercoating. That will finish the street side of the floor, and I can flip the teardrop right side up and put it back on the frame.

Things hopefully will then pick up. The hurricane hinge and my trim arrived from Grant (except for the roof edge trim. I still can't decide what style to use.) Most of my electrical components are purchased and ready to install. Wiring and the dreaded hatch construction are the next two dragons to slay.

Gig'em, Tom

)

) )

) )

)

Progress has been slow. Before the monsoon hit this weekend, my wife helped me pull the teardrop off the trailer to flip it over. I had some work to do on the belly side and thought it would be easier to do the work "bottoms up."

Progress has been slow. Before the monsoon hit this weekend, my wife helped me pull the teardrop off the trailer to flip it over. I had some work to do on the belly side and thought it would be easier to do the work "bottoms up."

Things hopefully will then pick up. The hurricane hinge and my trim arrived from Grant (except for the roof edge trim. I still can't decide what style to use.) Most of my electrical components are purchased and ready to install. Wiring and the dreaded hatch construction are the next two dragons to slay.

Things hopefully will then pick up. The hurricane hinge and my trim arrived from Grant (except for the roof edge trim. I still can't decide what style to use.) Most of my electrical components are purchased and ready to install. Wiring and the dreaded hatch construction are the next two dragons to slay.

I think it's a testament to Tom's strength that he can lift and flip something like that! It must weigh a few hundred pounds.

I think it's a testament to Tom's strength that he can lift and flip something like that! It must weigh a few hundred pounds.

Mark (& Cindi)

Mark (& Cindi)