madjack wrote:...if you want a true test, you should cut the treated part off and totally encapsulate that piece with your homebrew...THEN throw both pieces out into the cold cruel world and see how they both...individually...fare...elsewise, contamination from the untreated portion will make anything that happens to the treated portion a mute point.......

madjack

p.s.

Technical Data Sheet ...a pdf file

madjack that makes sense...i will totally encapsulate the piece and throw both pieces out in the yard and see what happens....BTW this where i got my idea from......

http://cgi.ebay.com/ws/eBayISAPI.dll?Vi ... 0074924441

MAX PCR

PROTECTIVE COATING RESIN

1 Gallon of Clear Resin

1/2 Gallon of Curing Agent

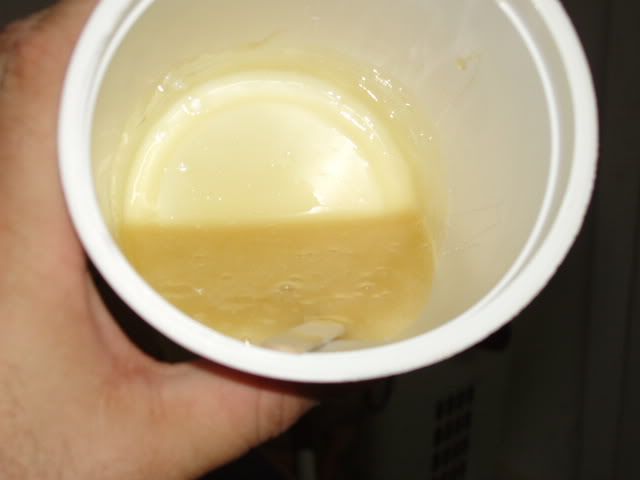

MAX PCR is a two-component epoxy based resin system formulated to provide a very long working time and low viscosity. It is specially designed as a protective coating and penetrating sealant against marine environment, water, alkali and acidic compounds. It exhibits excellent resistance to various solvents, microbial and fungal infestation preserving the wood' structural properties. It demonstrates excellent durability and exceptional adhesion to wood, metals, plastics and concrete substrates.

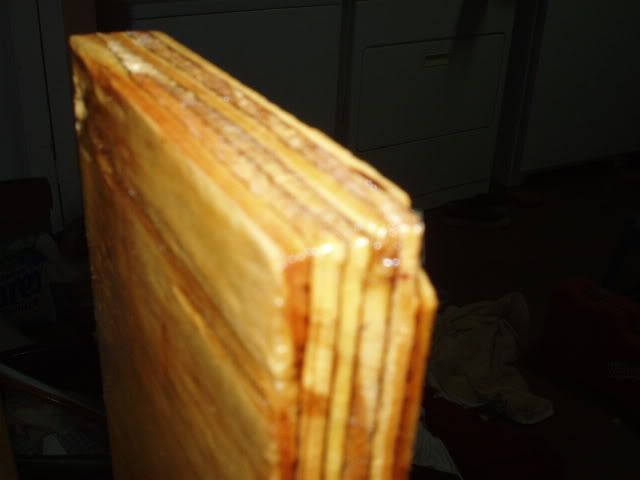

MAX PCR can also be utilized stabilize and encapsulate rotted or damaged wood and prevent further deterioration. It will stabilize damaged wood by filling the porosity retard fungal growth. The cured coating will have a high gloss and “blush-free” finish. For outdoor or direct sunlight exposure, directly apply several coats of latex or acrylic paint.

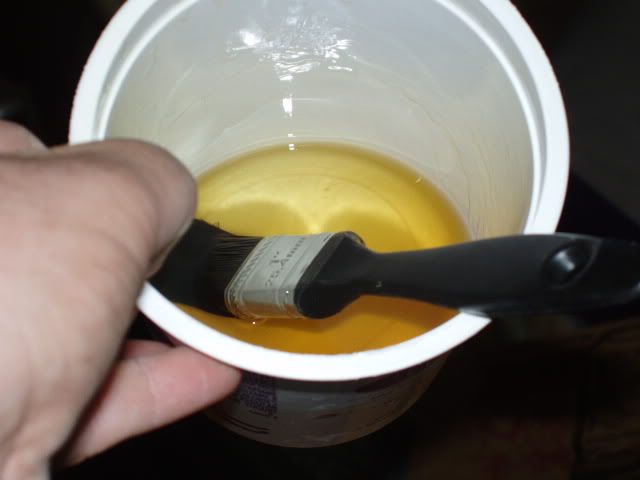

MAX PCR can withstand extreme cold temperatures and repeated thermal cycling without fracturing or peeling. It is resistant to deterioration due to wood tannin compounds, alkali from cementations materials and continuous water immersion. MAX PCR is supplied 100% solids (no solvent) and does not contain Ozone Depleting Chemicals. MAX PCR is easily mixed and applied using conventional application techniques such as roller or paintbrush. For spray applications, it can be further diluted with VOC exempt solvent such as acetone, TBAC (tertiary butyl acetate), perchlorethylene and other solvents. Adding solvents will also increase the penetrating properties when applied on wood or other porous materials and also extend the working time.

SAVE MONEY BY ADDING THE SOLVENT AT THE POINT OF USE

Reduced Packaging Cost

Lower Shipping Cost

Controlled Performance

Other Commerical Epoxy Penetrating systems contain highly toxic solvents such as toluene, naptha and other aromatic solvents that are also considered as an environmental pollutant.

MAX PCR is supplied solvent free to save cost on packaging and shipping of an easy to incorporate solvent or diluents that will effectively lower the viscosity of the mixed resin and make an excellent wood penetrant. Acetone is also considered as a None Hazardous Air Polluting Substance (None-HAPS) and is exempt under AQMD (Rule 102 Group 1, RULE 1107 and 1113) and EPA guidelines and mandates governing the release of petroleum based solvents.

http://www.aqmd.gov/rules/download.html

Using acetone as fast evaporating thinner, provides higher cured properties since the bulk of the acetone evaporates prior to the MAX PCR curing thus eliminating any plasticizing effect caused by the entrapped solvent within the resin matrix.

Compared to other systems that utilize slow evaporating solvents MAX PCR demonstrates higher wood penetrating and water proofing performance.

Acetone is widely available at most paint or hardware store and can be added at the time of use. Other solvents can be used but acetone demonstrates the best results. A 10% to 15% addition to the mixed MAX PCR resin provides excellent viscosity reduction and lowering of the epoxy resin's dynamic surface tension allowing deeper penetration while evaporating efficiently from the system. The fast evaporation and volatility of the acetone reduces any plasticizing effect upon cure of the resin matrix. Entrapment of any solvent within the cured epoxy matrix will eventually evaporate causing volume shrinkage, porosity and loss of water resistant properties. Any entrapped solvent will act as a fugitive solvent that will lower the water and chemical resistance of the cured resin.

Excellent water repellency

Reduced efflorescence

Water vapor permeability

Clear, uniform, neutral appearance

Reduced freeze-thaw damage

Long-term durability

Chloride ion resistance to deter reinforcing steel corrosion for concrete structures

Stain resistance from water and oil-based agents

Click on the picture to pause or play slide show

USE MAX PCR in other applications