One thing I've found in my research is that I'm just not smart enough to decipher all of the recommendations concerning the steel sizes to use for a teardrop trailer in the 1000-1200# range. (4.5 X 9 ft) This is a tough topic it seams! I've found all over the web suggestions by people explaining what size steel they have used to build their trailer, but I can't seem to find anything somewhat definitive as to the proper size that should be used.

My goal is to have a nice strong trailer for a teardrop, say something that is good up to 1500# to be safe, to build it as light as possible, but at the same time not be overkill and adding extra weight to the TD. Is there any definitive information or source anyone is aware of that will be fairly straightforward about steel sizing? I know I can, for example, use 3X3 1/4 square steel tubing for my trailer, but that would be overkill for a 1000-1500# trailer. How do you guys n gals know what size steel to use without going overboard and adding unnecessary extra weight?

Thanks in advance,

Fred

Trailer Steel Sizes

7 posts

• Page 1 of 1

Trailer Steel Sizes

Only a biker knows why a dog sticks his head out of a car window. ~Author Unknown

-

fseider - Teardrop Builder

- Posts: 34

- Images: 2

- Joined: Wed Oct 29, 2008 10:09 pm

- Location: Reading, PA

This is exactly why we try and refrain from discussing politics and religion on this forum. Frame size will be the next great argument ..........

Opinions on the optimum frame should run from PVC to rail road rails and many more ideas in between.

A good answer is as close as Lowes or Tractor supply just look over the 5x10 utility trailers out front if you are using a sprung axle.

a torsion axle places a bit more of a point load in 1 spot on each rail while a sprung axle places it in 2 points about 16 to 18 inches apart.

So there is your 1st fork in the road.

Now torsion box floor or just a sheet of plywood. A properly built torsion box floor actually requires NO frame other than an axle connection and a tongue and there are a few here that have been built just that way.

I used parts from a badly molested HF trailer for Chubby and for the barn I used a donor 5x8 utility trailer. I have my eye on a buddies 4x9 wave runner all aluminum for a 4x9 ultra light weight I would like to build this spring. More pics are in my album

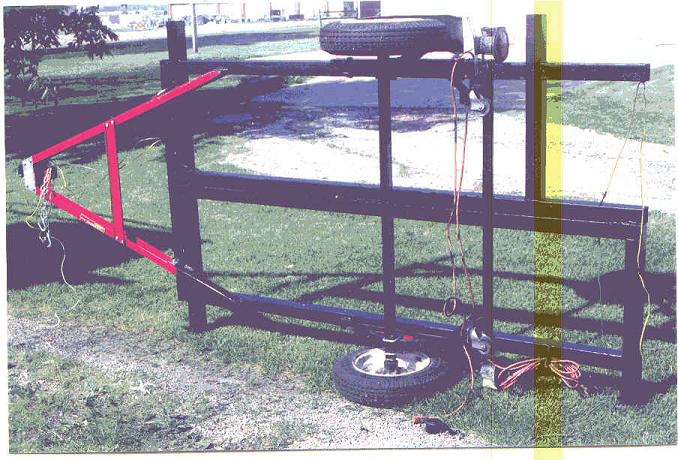

But this is my favorite , I think it is Planovets frame .

This thing is beautiful....

Opinions on the optimum frame should run from PVC to rail road rails and many more ideas in between.

A good answer is as close as Lowes or Tractor supply just look over the 5x10 utility trailers out front if you are using a sprung axle.

a torsion axle places a bit more of a point load in 1 spot on each rail while a sprung axle places it in 2 points about 16 to 18 inches apart.

So there is your 1st fork in the road.

Now torsion box floor or just a sheet of plywood. A properly built torsion box floor actually requires NO frame other than an axle connection and a tongue and there are a few here that have been built just that way.

I used parts from a badly molested HF trailer for Chubby and for the barn I used a donor 5x8 utility trailer. I have my eye on a buddies 4x9 wave runner all aluminum for a 4x9 ultra light weight I would like to build this spring. More pics are in my album

But this is my favorite , I think it is Planovets frame .

This thing is beautiful....

Growing older but not up !

-

bobhenry - Ten Grand Club

- Posts: 10368

- Images: 2623

- Joined: Fri Feb 09, 2007 7:49 am

- Location: INDIANA, LINDEN

), as we are talking about established engineering principles here for the sake of safety and practicality, not just wild guesses (I would hope!). (OK, engineers will differ of course, but their differences typically are fairly meaningless and trivial to the average layman.) Experience and personal 'rule of thumb' are great and valuable, but they do tend to vary widely form person to person, and again, subjective, not objective. How else does an inspector know what a trailer should be rated for? While it's easy enough to find information on the various characteristics of virtually any single shape of a piece of steel of any type, it's the tying it all together to form a single unit where an engineer's expertiese comes into play.

), as we are talking about established engineering principles here for the sake of safety and practicality, not just wild guesses (I would hope!). (OK, engineers will differ of course, but their differences typically are fairly meaningless and trivial to the average layman.) Experience and personal 'rule of thumb' are great and valuable, but they do tend to vary widely form person to person, and again, subjective, not objective. How else does an inspector know what a trailer should be rated for? While it's easy enough to find information on the various characteristics of virtually any single shape of a piece of steel of any type, it's the tying it all together to form a single unit where an engineer's expertiese comes into play.