by eamarquardt » Mon Apr 12, 2010 9:52 am

by eamarquardt » Mon Apr 12, 2010 9:52 am

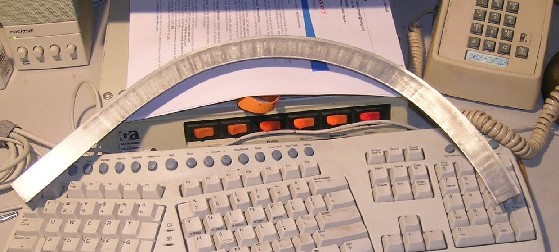

Sheet metal workers use things called shrinkers and stretchers to bend angles. I got a pair from Harbor Freight and bent this piece of 1X1X1/16 angle.

It roughs up the finish but you can sand and polish it up again.

As far as anealing goes I've done it with a propane torch. I've heard about sooting up the aluminum and heating till the soot disappears, and other techniques but what worked for me was to go in the garage at night, turn off the lights and use the propane torch to heat the aluminum till you could see it start to glow. Put the torch facing the inside of the angle and look at the outside. When you can see the glow, you know it's time to move on. In the dark, with the lights out it is easy to see and you just heat till it glows and work your way down the lenght of the piece you are annealing.

I once fit a piece of trim to my boat and did so using many c-clamps and blocks of wood to keep the flange from puckering (got 4 really nice c-clamps this weekend for 10 bucks at a garage sale, I digress). I think that I would make a template for the curve you want to bend out of scrap wood and do your bending on it rather than the teardrop itself. In addition, you could keep blocks of scrap wood clamped to the flange to reduce kinking while you bend it. You could do the curve in sections and not have to make a full sized pattern but use one piece of wood, recutting it a bit each time to match the section you're bending.

Hope this helps.

Cheers,

Gus

The opinions in this post are my own. My comments are directed to those that might like an alternative approach to those already espoused.There is the right way,the wrong way,the USMC way, your way, my way, and the highway.

"I'm impatient with stupidity. My people have learned to live without it." Klaatu-"The Day the Earth Stood Still"

"You can't handle the truth!"-Jack Nicholson "A Few Good Men"

"Some people spend an entire lifetime wondering if they made a difference in the world. The Marines don't have that problem"-Ronald Reagan

. It is kinking on the bend, getting marked because of the hammer and scratching the paint off the teardrop. Can anyone advise me what im doing wrong?...does it need to be hotter? Do i need to use a rubber hammer? is the radius of the bend too tight for aluminium to bend round?

. It is kinking on the bend, getting marked because of the hammer and scratching the paint off the teardrop. Can anyone advise me what im doing wrong?...does it need to be hotter? Do i need to use a rubber hammer? is the radius of the bend too tight for aluminium to bend round?

. So once the metal has been heated, do you have to bend it while it is hot or will it remain flexible when it has cooled down?

. So once the metal has been heated, do you have to bend it while it is hot or will it remain flexible when it has cooled down?