DD, on the road to LCG

Yes, finding those 4 bowls was a nice surprise. A touch of cowboy Americana. I plan to store them in the galley and use them on occasion.

-

StPatron - Donating Member

- Posts: 748

- Images: 297

- Joined: Tue Dec 15, 2009 8:38 pm

- Location: OK

Been kinda busy lately, here's a re-cap. I went out to the shop the next morning expecting to see nicely adhered vinyl on the bumpy wall,,,,, NOT! The contact cement decided to fail me in the middle of the night, rascal. That's ok, though. That area will be covered with an upper cabinet and a small counter below with a basin for tooth-brushing and face-washing. In between,,, a rectangular wall mirror maybe???

I hadn't made a final decision about what to do with the bathroom wall corners. Maybe run a bead of silicone and then add trim? Then, I was reading "fromeo's" build thread and saw the vinyl welt he used. Ah! That's perfect. Here's a link to that thread:

http://www.mikenchell.com/forums/viewtopic.php?p=687894#687894

Hmmm, I wanted to do it today so that I could secure the aft bulkhead and begin the desk/bathroom divider wall. Home-made welt? Why not? I had enough vinyl left-overs that could be cut into strips. I could then encase a piece of rope in the strips and staple them in place. It would've been easier to pre-fab the welt strips but after my recent experience with failing adhesives, I decided to "welt in-situ".

From the back side of the bulkhead I slid the vinyl strip in the gap and stapled one edge, then went inside the cabin to place the rope and fold the vinyl back over and slip it back into the gap. Back to the other side of the bulkhead, pull tightly and staple. Worked pretty good but I had to make about 27 round-trips!

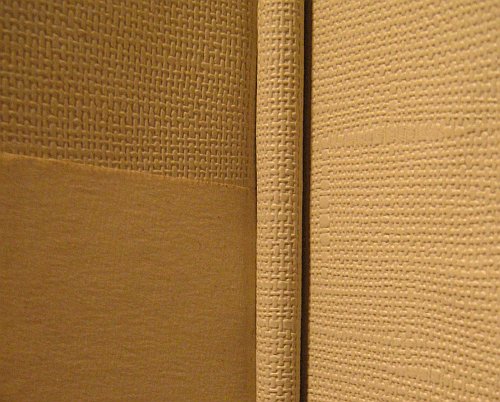

The materials used:

This strip was too narrow, making it difficult to grab it after it was wrapped around the rope. I later cut a much wider strip and trimmed excess after stapling.

I was happy with how it turned out and think it will provide a water-proof seal. The nylon rope floats,, hope I don't have to witness that first-hand.

Pre-fabbing the welt strips would be much faster and easier to apply. I may use that technique in other areas,,, using cloth or other materials that can be sewn. Or, I may just use that flexible trim sold in the box-stores or the vinyl welt that "fromeo" used. Lotta options. Another challenge overcome today, love it!

I hadn't made a final decision about what to do with the bathroom wall corners. Maybe run a bead of silicone and then add trim? Then, I was reading "fromeo's" build thread and saw the vinyl welt he used. Ah! That's perfect. Here's a link to that thread:

http://www.mikenchell.com/forums/viewtopic.php?p=687894#687894

Hmmm, I wanted to do it today so that I could secure the aft bulkhead and begin the desk/bathroom divider wall. Home-made welt? Why not? I had enough vinyl left-overs that could be cut into strips. I could then encase a piece of rope in the strips and staple them in place. It would've been easier to pre-fab the welt strips but after my recent experience with failing adhesives, I decided to "welt in-situ".

From the back side of the bulkhead I slid the vinyl strip in the gap and stapled one edge, then went inside the cabin to place the rope and fold the vinyl back over and slip it back into the gap. Back to the other side of the bulkhead, pull tightly and staple. Worked pretty good but I had to make about 27 round-trips!

The materials used:

This strip was too narrow, making it difficult to grab it after it was wrapped around the rope. I later cut a much wider strip and trimmed excess after stapling.

I was happy with how it turned out and think it will provide a water-proof seal. The nylon rope floats,, hope I don't have to witness that first-hand.

Pre-fabbing the welt strips would be much faster and easier to apply. I may use that technique in other areas,,, using cloth or other materials that can be sewn. Or, I may just use that flexible trim sold in the box-stores or the vinyl welt that "fromeo" used. Lotta options. Another challenge overcome today, love it!

-

StPatron - Donating Member

- Posts: 748

- Images: 297

- Joined: Tue Dec 15, 2009 8:38 pm

- Location: OK