Sorry to be late to the party - been a busy week at work.

A 2.5x2.5x3/16 single tongue passes the Australian trailer rules for a 1500lb trailer, but I now think teardrops can double that rating and still be safe. This trailer is a bit of a halfway house between a teardrop and a utility trailer, so that 2.5x2.5 looks OK, though with no spare meat on it.

I second the practical concerns about getting a 2.5x2.5 to slide inside a 3x3x1/8 - if it's going to be slideable, it will have what an old engineer taught me to call a "rattling good fit". That means it will rattle all the time so some way of taking up both the horizontal and the vertical free play would be a good idea.

Receivers don't have a long overhang like tongues so an accessible locking pin doesn't cause a weakness in them. But in a tongue receiver it makes me scream - it reduces the stength of the tongue just at the point of maximum bending. So I would like to see the locking pin moved at least 12" back from the front end of the receiver - I know getting to the pin now involves kneeling or lying on the ground, but that is much, much better than a broken tongue....

The Australian rules say that the single tongue will be just strong enough sideways on its own, but that doesn't guaranteee that the flexibility of the single tongue won't give a shimmy problem, as it has to a couple of forum members. But it would be a shame to have diagonals in the way if they're not really needed.

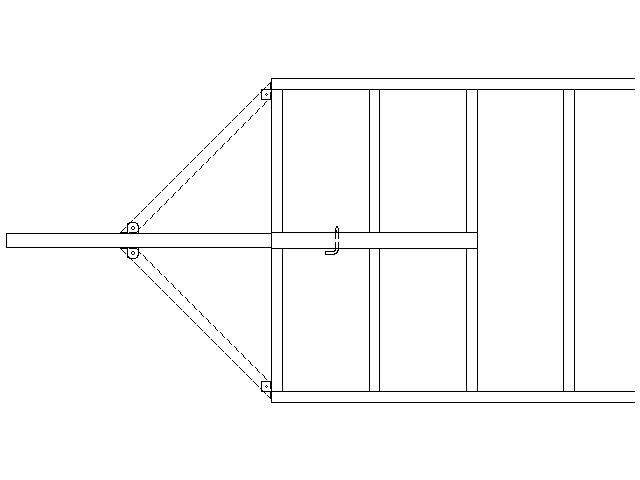

So my suggestion is to fit it "for but not with" diagonals - brackets welded on the tongue and front cross-member could take diagonals if they are found to be needed or could easily be cut off if not required. With nicely rounded corners they shouldn't do too much shin damage. The ones on the tongue could have bolts so the diagonals stay attached to it when the tongue is out, but will still fold up for easy storage. Pins would be used in the cross-member brackets. Both the bolts and the pins need to be tight fits if they are to work well - too much slop here won't stop the shimmy, just move it to a different speed.

So here's what I've got: