I calculated a differece of about 2.3". So, using a table saw, I cut 18 kerfs spaced 1" apart. Tomorrow I will glue it up with Gorilla glue and tape it in place until it dries. Just bending it seems to make a perfect 12" radius to 90 degrees. The glue will fill the voids at the bottom of the kerf cuts also.

Thrifty Alternatives ..Building Foam Campers

Moderator: eaglesdare

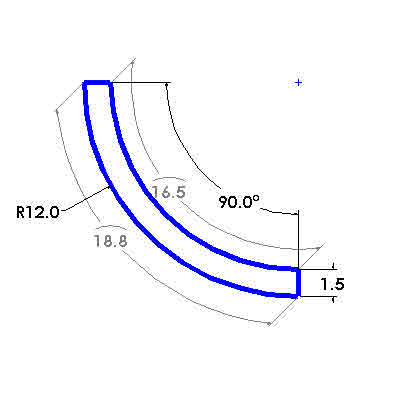

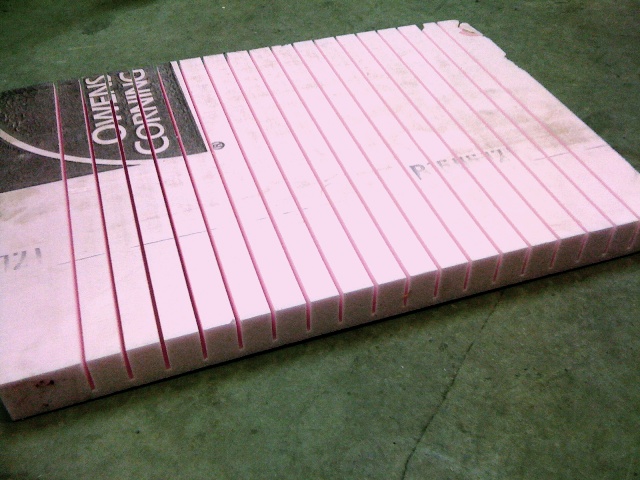

Okay, I found a scrap piece of 1.5" foam. Its 15"x21" and I'm going to put a 12" radius in it to 90 degrees.

I calculated a differece of about 2.3". So, using a table saw, I cut 18 kerfs spaced 1" apart. Tomorrow I will glue it up with Gorilla glue and tape it in place until it dries. Just bending it seems to make a perfect 12" radius to 90 degrees. The glue will fill the voids at the bottom of the kerf cuts also.

I calculated a differece of about 2.3". So, using a table saw, I cut 18 kerfs spaced 1" apart. Tomorrow I will glue it up with Gorilla glue and tape it in place until it dries. Just bending it seems to make a perfect 12" radius to 90 degrees. The glue will fill the voids at the bottom of the kerf cuts also.

I make stuff, and it's all designed on Post-Its... the small ones.

-

HandyAtLeast - Teardrop Builder

- Posts: 41

- Images: 22

- Joined: Tue Apr 12, 2011 12:54 pm

- Location: Puget Sound

Hey guys I had a piece of 1" foam with luan on one side and cloth on the other. this cloth is put on with latex primer instead of T2 but it is a 8" by 2" piece I tore the luan off the back side and as you can see it is bent double with out breaking.

Gary

Gary

-

RAYVILLIAN - Lifetime member

- Posts: 1434

- Images: 109

- Joined: Thu Aug 05, 2004 9:33 pm

- Location: Rayville MO

The ribbed plywood hatch on my 6X12 TD was HEAVY ..cumbersome to use /prop up... Now I'm wondering about a bent foam hatch ... cloth covered as usual ... One of the benefits of foam is when it's bent with heat , it stays in that position permanently ... I've made Many cambered wings in the past , airfoil shaped ... they keep their shape forever... 1' foam would be all you need for a hatch really ... that would be easy to heat and bend to a hatch shape ... Sure would be light , and if it hit you in the head , wouldn't leave a flat spot ...

The ribbed plywood hatch on my 6X12 TD was HEAVY ..cumbersome to use /prop up... Now I'm wondering about a bent foam hatch ... cloth covered as usual ... One of the benefits of foam is when it's bent with heat , it stays in that position permanently ... I've made Many cambered wings in the past , airfoil shaped ... they keep their shape forever... 1' foam would be all you need for a hatch really ... that would be easy to heat and bend to a hatch shape ... Sure would be light , and if it hit you in the head , wouldn't leave a flat spot ...  Just more ideas ...

Just more ideas ...