Thrifty Alternatives ..Building Foam Campers

Moderator: eaglesdare

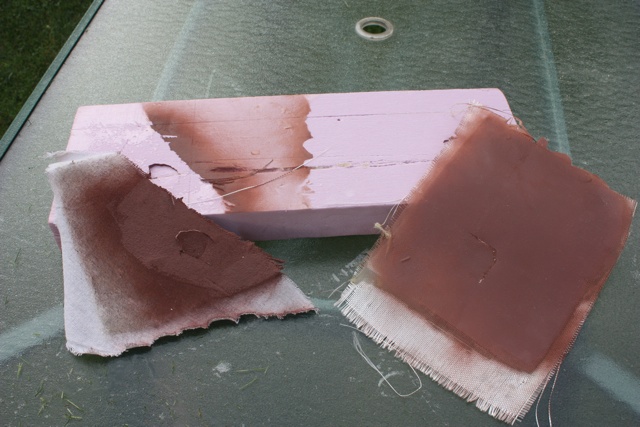

it happened to davel on the Bluebonnet II build. His was a foam core covered with fiberglass cloth and epoxy resin - on some places it did bubble.

-

starleen2 - 5th Teardrop Club

- Posts: 16272

- Images: 224

- Joined: Sat May 12, 2007 8:26 pm

- Location: Pea Ridge ,AR

One reason to paint it White or a light color ...  Our Southern sun is Very Hot , and any dark color really turns up the heat on the materials used ... The black areas on my Camo job get so hot they will give you a 3rd degree burn ... ask me how I know ...

Our Southern sun is Very Hot , and any dark color really turns up the heat on the materials used ... The black areas on my Camo job get so hot they will give you a 3rd degree burn ... ask me how I know ...

That , and the perforated foam should solve this problem ... better attachment , less Heat ...

Another consideration is Moisture under the glass , glassing is best done on a DRY day , on a DRY, Clean surface ...

Our Southern sun is Very Hot , and any dark color really turns up the heat on the materials used ... The black areas on my Camo job get so hot they will give you a 3rd degree burn ... ask me how I know ...

Our Southern sun is Very Hot , and any dark color really turns up the heat on the materials used ... The black areas on my Camo job get so hot they will give you a 3rd degree burn ... ask me how I know ...

That , and the perforated foam should solve this problem ... better attachment , less Heat ...

Another consideration is Moisture under the glass , glassing is best done on a DRY day , on a DRY, Clean surface ...

There’s no place like Foam !

-

GPW - Gold Donating Member

- Posts: 14920

- Images: 546

- Joined: Thu Feb 09, 2006 7:58 pm

- Location: New Orleans