D. Tillery wrote:Andrew, I have a question. Are your figures for angle placed in that manner, without one side of 1"x1/4" placed hardway?

Yes, the numbers relate exactly to the section shown in Bandit's picture - that's why I had to hand-crank the answer, as I don't have a spreadsheet written to calculate properties of angles at 45 degrees from normal!

asianflava wrote:Is this more or less effective as a tension strap welded to the bottom of the tongue?

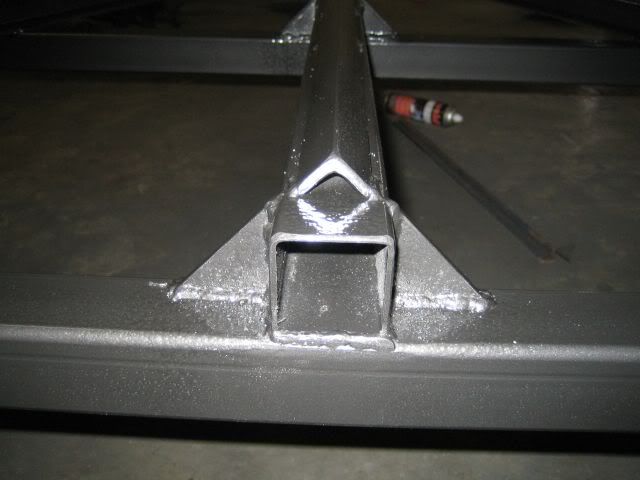

I'm not sure what 'tension strap' means here. If you mean a flat bar lying against the bottom of the square tube, then this 'added angle' will be much stronger.

If you mean the 'small truss' type of reinforcement (for example, as proposed by Guy) with a flat bar propped some way undeneath the square tube, then I would expect that to be a good bit stronger than this 'added angle' method. However this method does provide constant strength along the tongue - it is easy to design the 'small truss' reinforcement wrong so that it doesn't actually add much strength.

Andrew

Some of the time anyway

Some of the time anyway