Ultralight Design?

Gee..i'm doing a moderistic, full size, with minimal frame for axles and tongue, 1/4 inch luan on the inside, framed and covered with cloth and paint..i wonder if it will be light?..

Jim in Savannah

If you can read this bumper sticker, my camper fell off.

If you can read this bumper sticker, my camper fell off.

-

Jiminsav - 3000 Club

- Posts: 3059

- Images: 40

- Joined: Sat Apr 17, 2004 8:49 pm

- Location: Georgia, Savannah

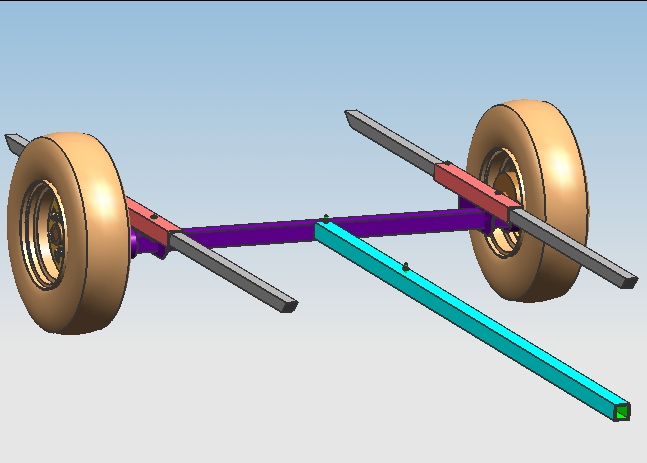

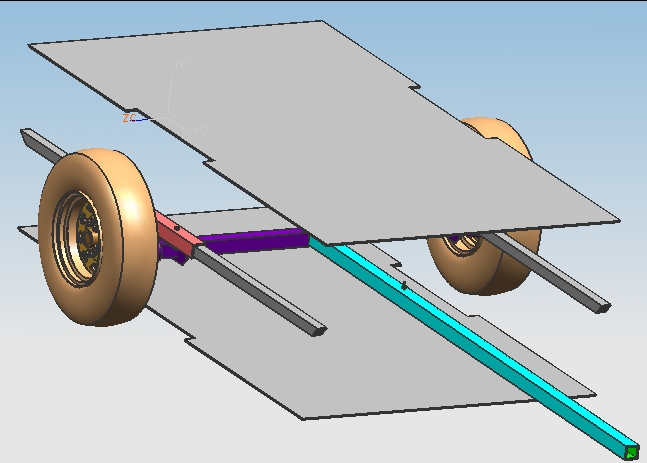

Hey Andrew,

I'm impressed... you gained me some extra space without extra weight... I like the way you think...

Okay, let's talk floorboards...

I'm thinking either a torsion box (aka a hollow core door) or a rigid panel covered only on the top with a couple layers of 1/4" luan... 1/2" baltic birch plywood would be a better choice, I'm sure...

But more importantly, each of the edges is a 2x? piece of oak so that I've got some material to bolt the axle to...

So if each side is a 2x3 piece of oak, with a piece of 1/2" plywood on top... then the bolt has to go thru 2" of wood (1 1/2" of oak and 1/2" of baltic birch). That should hold up, don't you think?

Now the tongue, that's another question indeed... at first thought, I'm thinking a straight tongue, that we can bolt a couple onto... This tongue can be 2x2 or 2x3... your choice... but what do we fasten it to? We could run a bolt thru the floor and thru the tongue, every foot or so. The floor would have to disintegrate for the tongue to come loose.

Your thoughts...

Mike...

I'm impressed... you gained me some extra space without extra weight... I like the way you think...

Okay, let's talk floorboards...

I'm thinking either a torsion box (aka a hollow core door) or a rigid panel covered only on the top with a couple layers of 1/4" luan... 1/2" baltic birch plywood would be a better choice, I'm sure...

But more importantly, each of the edges is a 2x? piece of oak so that I've got some material to bolt the axle to...

So if each side is a 2x3 piece of oak, with a piece of 1/2" plywood on top... then the bolt has to go thru 2" of wood (1 1/2" of oak and 1/2" of baltic birch). That should hold up, don't you think?

Now the tongue, that's another question indeed... at first thought, I'm thinking a straight tongue, that we can bolt a couple onto... This tongue can be 2x2 or 2x3... your choice... but what do we fasten it to? We could run a bolt thru the floor and thru the tongue, every foot or so. The floor would have to disintegrate for the tongue to come loose.

Your thoughts...

Mike...

The quality is remembered long after the price is forgotten, so build your teardrop with the best materials...

-

mikeschn - Site Admin

- Posts: 19202

- Images: 475

- Joined: Tue Apr 13, 2004 11:01 am

- Location: MI

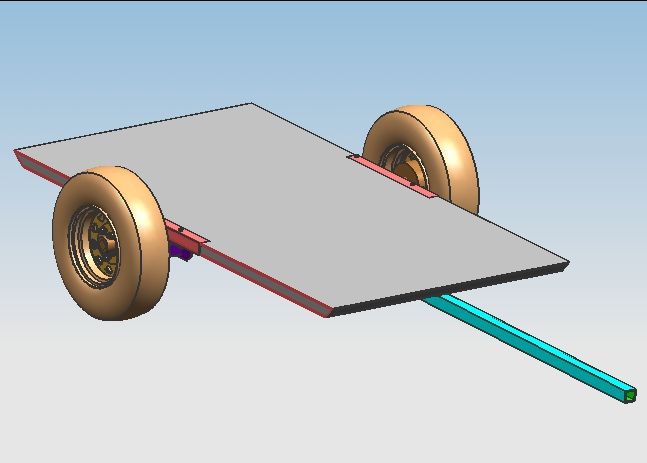

How many test miles before putting the teardrop on top??? You can tow it over to my house and back to see how it works

How many test miles before putting the teardrop on top??? You can tow it over to my house and back to see how it works