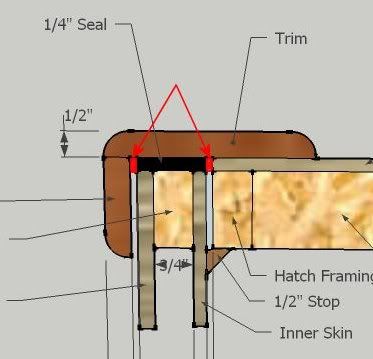

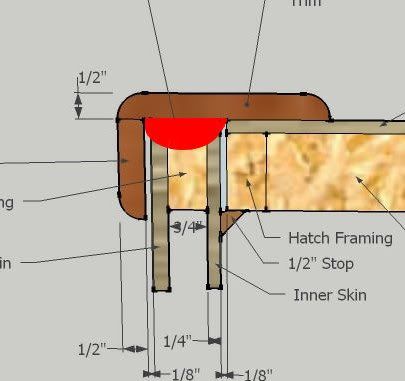

how I would seal the galley hatch and this is the solution I came up with, based on where I stand now in construction.

how I would seal the galley hatch and this is the solution I came up with, based on where I stand now in construction.

I'm thinking it shouldn't have any problems, however I just wanted to get your thoughts before I commit to more of my framing and such. Keep in mind this is a woody and the trim is 1/2" thick (actual thickness).

One thought I had was to eliminate the 2 seals and go to just one by lowering the side trim and moving the 1/4" seal to the outside edge.

I also considered moving the top trim over to create a "drip edge" of sorts.

Thoughts?

Below is a cross section of the hatch.

Yep, you have over-built it!

Yep, you have over-built it!  Looks good to me really!

Looks good to me really!

Mark (& Cindi)

Mark (& Cindi)

Thanks

Thanks

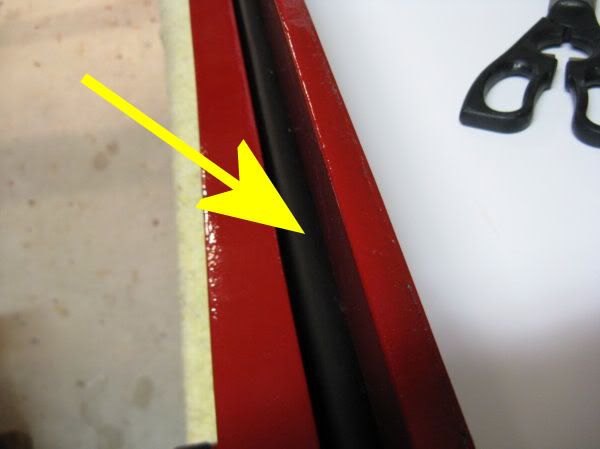

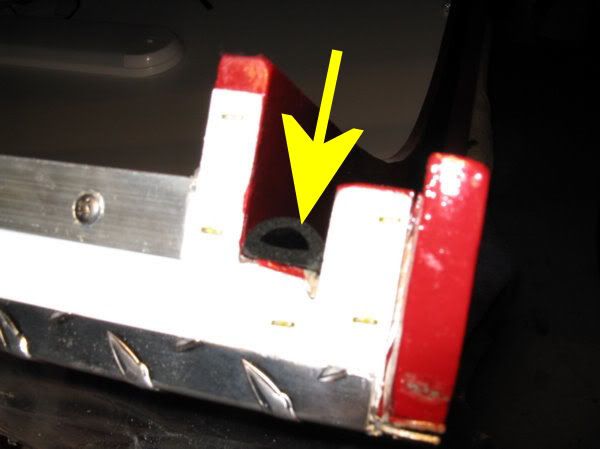

Thanks for the pics as well

Thanks for the pics as well