After looking at travel trailers, tent trailers my wife and I have decided to tackle a tear drop. And with that comes my first set of questions.

As of right now just about every camp we go to involves some sort of off road driving, so strength and rigidity are a couple of my main concerns. Through my work I have access to welders and plenty of materials, so welding up or adding/cutting something is not a big deal.

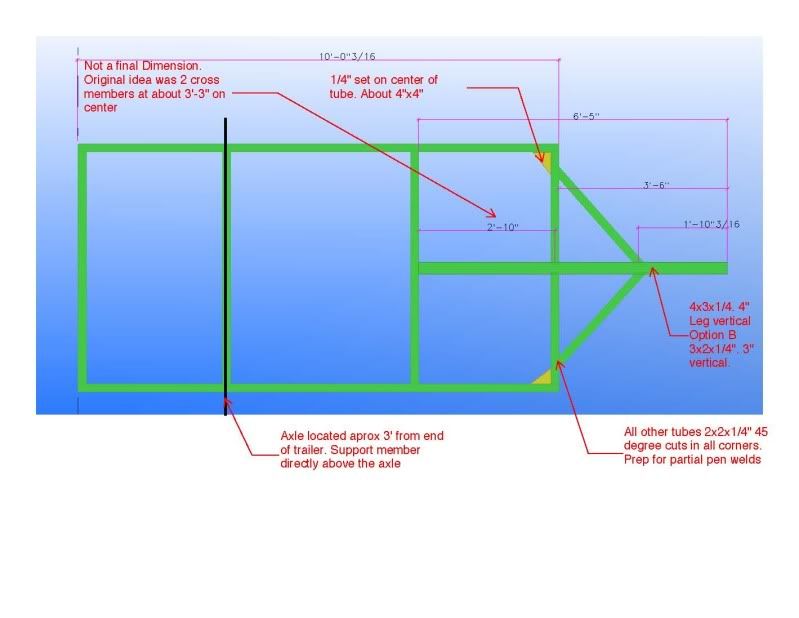

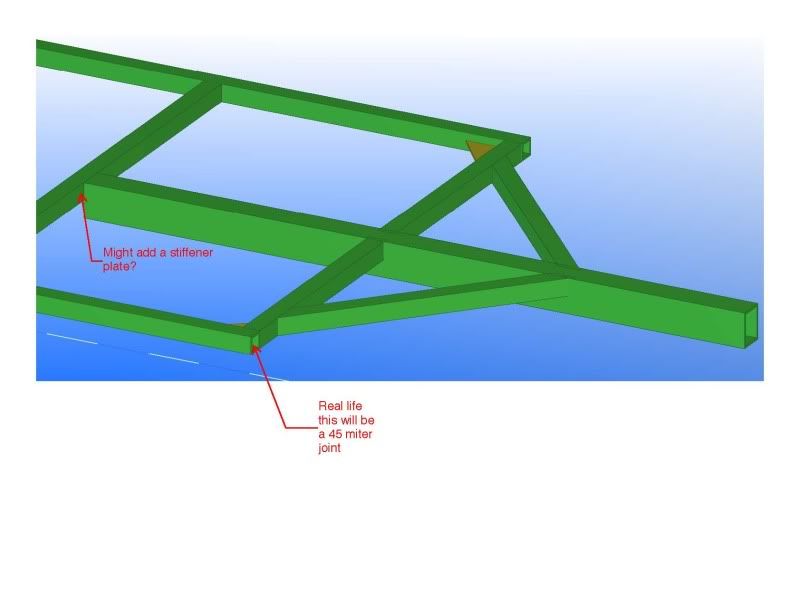

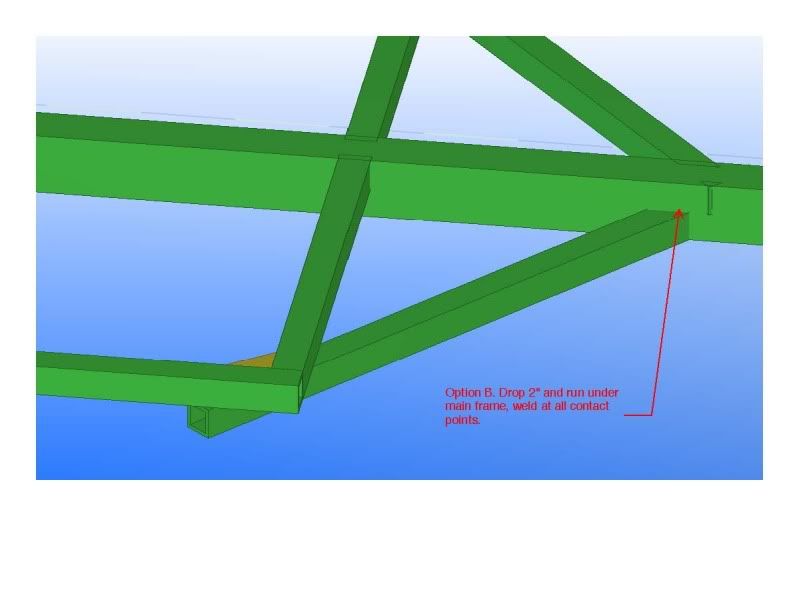

I have the option of building my trailer out of 2x2x1/4 tube as opposed to the 1/8 that most people seem to run. The weight penalty is about 2 lbs a foot of tube. About 100 lbs total. But i think I can run 1/4 ply as the base because it will not have to take the same load as it would by using the 1/8 tube and 3/4 ply. The other reason for the 1/4 tube is the cost. I can get "scrap" tube from work for basically pennies a pound, if i go with the 1/8 I will have to order it in and pay full price. With that cost savings and the saving of the thinner ply it seems to make sense.

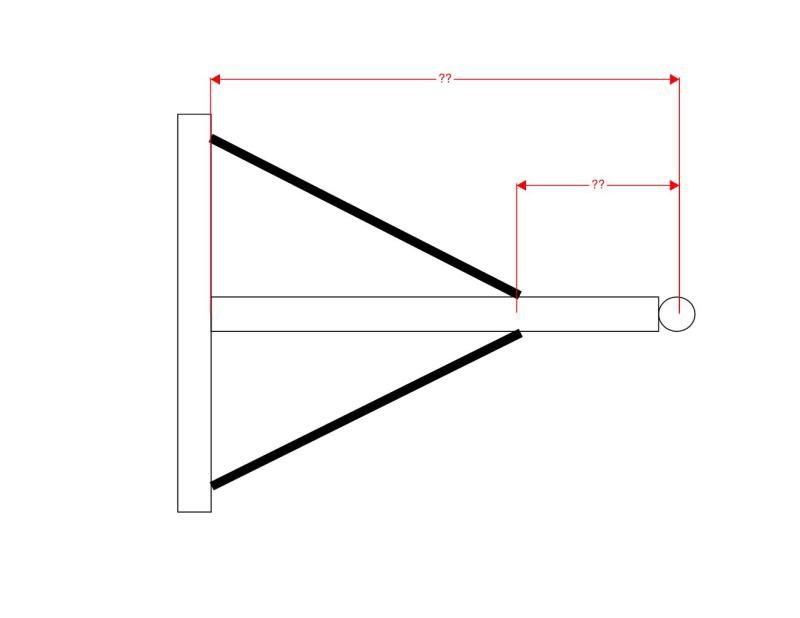

I have been looking around for a dimension from the ball to the front of the trailer. I believe it is going to be about 3'. If anyone can give me a hand on this it would be of great help.

Last are the axles. I would like to do an axle that runs the same bolt pattern as my truck, and i would like to run the same size wheels/tires (15") I am a bit concerned about 8" or 12" trailer wheels and tires going off road. I am really scared of cutting a tire because of the size and the amount of rocks we tend to run into in the desert. Any feedback on this??? If i need to buy an axle and stretch it to get the correct hub to hub dimension is not a big deal.

Thanks for any and all information!!!