Seaboard as an alternative to plywood?

http://worldpanel.com/seaboard.htm

I've had nothing but problems with plywood

63 posts

• Page 5 of 5 • 1, 2, 3, 4, 5

Re: I've had nothing but problems with plywood

Waiting for "someday" will leave you on your deathbed wondering why you didn't just rearrange your priorities and enjoy the time you had, instead of waiting for a "better" time to come along...

-

48Rob - Super Lifetime Member

- Posts: 3882

- Images: 4

- Joined: Thu Nov 17, 2005 6:47 pm

- Location: Central Illinois

Re: I've had nothing but problems with plywood

Rob, I've used a tone of that stuff on boats (though called SeaTeak or StarBoard). It will certainly be weatherproof and is inherently waterproof, but...

It's virtually impossible to glue it and, like the comments on using plastic decking, its strength/weight ratio is dismal.

It's great for things like fish tables and stair treads, but it's generally screwed onto an existing frame or substrate.

If you could overcome that, it would be a great material for a build. It's good for counters except that it's not heat resistant...but you can use your counter as a cutting board, then hit it with the any cleaner/disinfectant you want. I plan to use a piece of 3/4 I have to make a drop-in cutting board for over the sink.

If you used a single piece of 1/4" for the roof on a tear, you would still need internal bracing to keep it from sagging, but if it sagged and water pooled, it wouldn't cause problems unless there was a screw hole there.

Polysulfide sealants are about the only thing that (sort of) sticks to it, the primer and adhesive made specifically for it work about as well but they're an extra step. Both need to be backed up by mechanical fasteners.

On the plus side, it would be absolutely zero maintenance and pulling it through the car wash would have it looking brand new again. The black doesn't show scuffs and scratches much, the white doesn't at all.

But it's all JMHO of course.

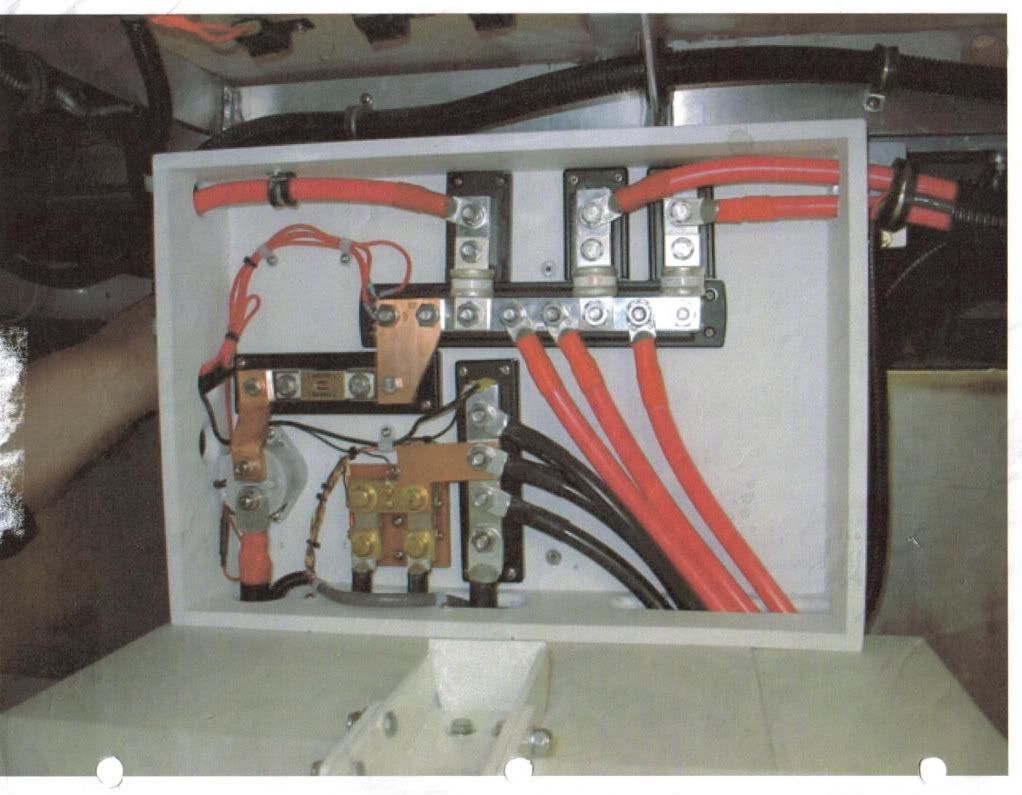

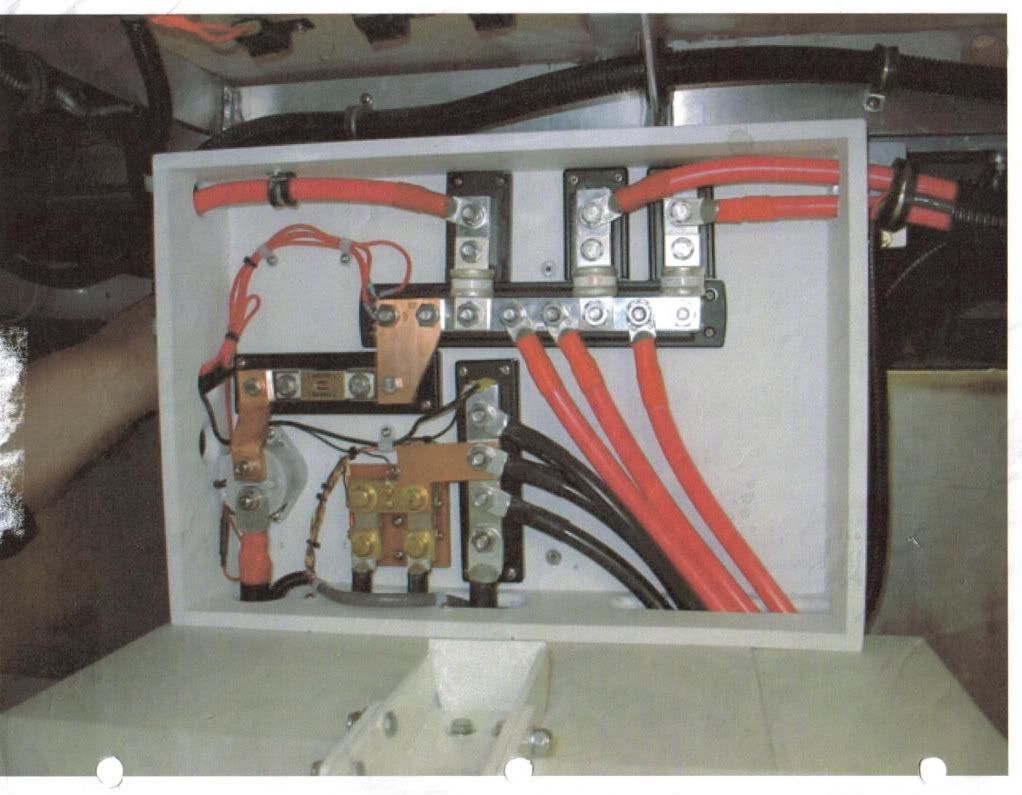

Here's a bus panel for a battery bank that I made out of it:

The box is screwed together and I used it here because I wanted a nonconductive alternative to wood or glass.

Personally I would have made a mold and used fiberglass, but the company I was working for advertises that there's no fiberglass used anywhere on their (metal) boats. It takes a screw about as well as hardwood, but needs to be predrilled.

It's virtually impossible to glue it and, like the comments on using plastic decking, its strength/weight ratio is dismal.

It's great for things like fish tables and stair treads, but it's generally screwed onto an existing frame or substrate.

If you could overcome that, it would be a great material for a build. It's good for counters except that it's not heat resistant...but you can use your counter as a cutting board, then hit it with the any cleaner/disinfectant you want. I plan to use a piece of 3/4 I have to make a drop-in cutting board for over the sink.

If you used a single piece of 1/4" for the roof on a tear, you would still need internal bracing to keep it from sagging, but if it sagged and water pooled, it wouldn't cause problems unless there was a screw hole there.

Polysulfide sealants are about the only thing that (sort of) sticks to it, the primer and adhesive made specifically for it work about as well but they're an extra step. Both need to be backed up by mechanical fasteners.

On the plus side, it would be absolutely zero maintenance and pulling it through the car wash would have it looking brand new again. The black doesn't show scuffs and scratches much, the white doesn't at all.

But it's all JMHO of course.

Here's a bus panel for a battery bank that I made out of it:

The box is screwed together and I used it here because I wanted a nonconductive alternative to wood or glass.

Personally I would have made a mold and used fiberglass, but the company I was working for advertises that there's no fiberglass used anywhere on their (metal) boats. It takes a screw about as well as hardwood, but needs to be predrilled.

-

Wobbly Wheels - Donating Member

- Posts: 1080

- Joined: Tue Mar 15, 2011 9:51 am