Per my introductory post in the Newbie section http://www.tnttt.com/viewtopic.php?f=40&t=50713 here is a time line and some construction photos.

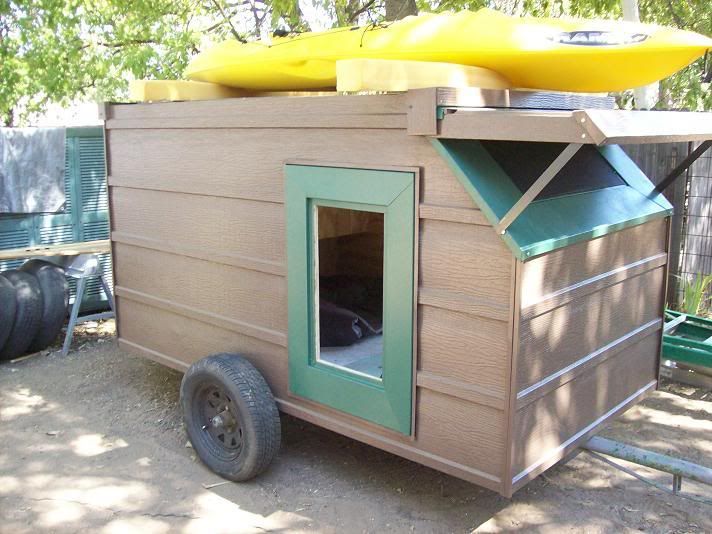

My goal was to build an enclosed trailer as quickly and cheaply as possible maximizing salvage and surplus materials I had accumulated over several years. Its purpose was to hold all my camping and outdoor equipment, be easily set up, and fully self contained suitable for year round use. It was built in 2 weeks in the fall of 2011 and my cash outlay was approximately $200 for hardware and accessories.

Trailer - I did not take any photos. The trailer was given to me. It had been home built using an old automobile drop axle with a tread width of approximately 56 inches riding on leaf springs. The steering arms of the spindles had been welded in place with good caster and camber. The hubs are 5 bolt 4.5 inch pattern with 14 x 6 inch rims. It pulls well and true. The frame consisted of a pair of 2 inch square tube rails and three 2x2 angle iron crossmembers forming a bed approximately 4 x 8 feet. The tongue was a 2.5 inch round tube extending from the center crossmember to about 4.5 feet forward of the bed. I moved the axle to 44 inches from the back of the bed and 52 inches from the front of the bed and added a fold-up jack. I also added two pieces of 1 x 1 inch angle iron from the front of the tongue to each side of the front crossmember for reinforcement and to support the tongue box to be added later.

Floor is 3/4 inch pressure treated plywood topped by 1/8 inch masonite. It is screwed and glued to pressure treated 2 x 4s around the perimeter underside which are bolted to the front and read crossmembers. The floor rests on the two rails which are approximately 36 inches apart and the three crossmembers which are 24 inches apart.

Side and front walls are 3/4 inch exterior grade plywood (CDX) screwed and glued to the outside of the perimeter 2 x 4 creating an interior 48 inches wide and 44 inches in height. The front wall was cut back at the top 45 degrees for about 12 inches.

Roof spars are 2 x 3 on edge 16 inches on center resting on top of the side walls with a 1/4 inch plywood ceiling glued to the underside. The void was filled with solid urethane insulation and topped with 1/2 plywood to support the roof. The other half and cut off of the front wall was used for the rear bulkhead which is set 16 inches from the rear at floor level up 24 inches and 28 inches from the rear at the top creating a bed area of 48 x 80 inches.

Most of the plywood was weathered on the outside from sun and rain exposure but solid with no delamination, mold or rot. The inside was sanded and sealed with clear polyurethane.

TTT # 1 - Quick and Cheap

27 posts

• Page 1 of 2 • 1, 2

TTT # 1 - Quick and Cheap

Last edited by M C Toyer on Thu Jun 14, 2012 11:13 pm, edited 4 times in total.

-

M C Toyer - The 300 Club

- Posts: 363

- Images: 11

- Joined: Thu May 31, 2012 8:59 pm

- Location: Pilot Point (Denton County) Texas

Re: TTT # 1 - Quick and Cheap

The side door openings were cut out and the outside walls were strapped with 3/4 inch plywood scraps glued and screwed at the corners, around the door openings, and in between on approximately 24 inch center:

The voids were filled with a double layer of 3/8" foil faced urethane insulation with the foil in the center:

A window opening was cut in the angled section of the front wall:

The entire exterior and roof was covered with house wrap:

The base of the walls and bottom of the 2 x 4 perimeter of the floor were capped with 26 ga steel sheeting:

The voids were filled with a double layer of 3/8" foil faced urethane insulation with the foil in the center:

A window opening was cut in the angled section of the front wall:

The entire exterior and roof was covered with house wrap:

The base of the walls and bottom of the 2 x 4 perimeter of the floor were capped with 26 ga steel sheeting:

-

M C Toyer - The 300 Club

- Posts: 363

- Images: 11

- Joined: Thu May 31, 2012 8:59 pm

- Location: Pilot Point (Denton County) Texas