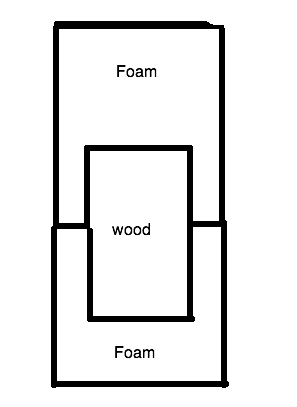

The idea of using the 1X2 framing was actually Steve’s (linuxman) idea , which is very practical when you can’t find thicker foam (everybody seems to stock the 3/4” foam )... The idea was to fit the framing thickness to the thickness of the foam , then the outer layer is glued over all that ( for more insulation and a uniform surface ) and all that covered with canvas... or glass should you choose that route ...

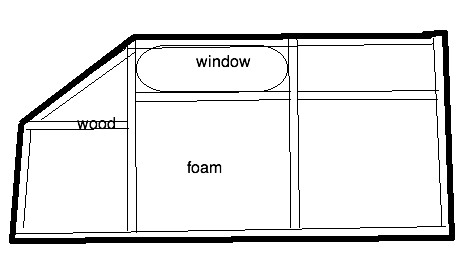

Like KC said , it helps to have a Plan on where you’re going to locate everything , so attachment points can be attached before the finish skin goes on ...

You could do a dowel and plate style hard point for lighter things (after the fact) , but for shelves, bed frames, etc , you might need More bracing and that should be considered prior to the build ...

The current thinking for my new build is to use sliced sheets of 3.5” thick beadboard , which BTW fits standard 1X4 ( 3/4” X 3 1/2” ) lumber... again making building easy, just simple cross cutting of standard lumber , no custom woodwork , which requires more advanced tools , ..

You could do a dowel and plate style hard point for lighter things (after the fact) , but for shelves, bed frames, etc , you might need More bracing and that should be considered prior to the build ...

You could do a dowel and plate style hard point for lighter things (after the fact) , but for shelves, bed frames, etc , you might need More bracing and that should be considered prior to the build ...