Okay, now where the heck were we?

Let’s see. There was some talk about a lamb roast done on an open hearth.

Spit is gravity powered by a weight compounded through antique wooden pulleys and the escapement; an 18th century English clock jack.

Note the whirling propellers that create drag and help regulate the rate that the weight drops.

Mom & Bill’s dining room.

Note the rosemary sprigs tucked under the butcher’s twine.

There was also a chicken done on the gas grill rotisserie.

Back to the build… er… work shop improvement; hanging plastic sheet to keep heat in through the cold New England winter.

Here I have measured and cut a piece of plastic to finish the ceiling and drape wall, starting to spread it out over the saw and layout table.

Started to tack up and spread out, working along the first joist, then up the middle, before moving back out to the sides.

After tacking off the next to last ceiling joist, I switched and tacked the drape wall to the inside face of the last joist so that the staples would be loaded in shear and not just pull out. Blue tape at the wall to ceiling joint (would have used standard duct tape if I had it on hand; the blue tape dosen’t have much stick, especially after the static cling of the plastic has picked up shop dust).

Made a cut for the door; attached the big piece I had cut out from the big window to act as a flap overlapping the door; and then spent some time putting stuff back and reorganizing.

And from the outside.

Stopped at Wally World to get an electric heater for the loft and got a chance to get a couple of pics of this barrel vaulted homebuilt topper that I had seen around. Reminded me of the Foamstream and all of the aero talk that has been going on elsewhere on the forum.

Here’s the heater that I picked up.

Then I finally spent some time doing actual work on the camper. Sanded the high spots on the filler and misc glue spots on the underside of the floor.

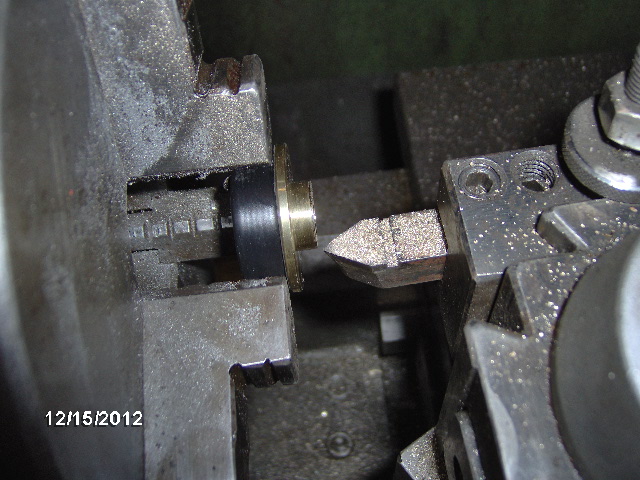

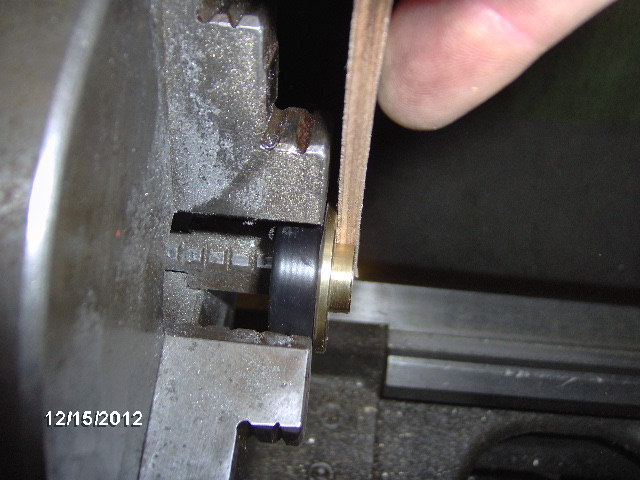

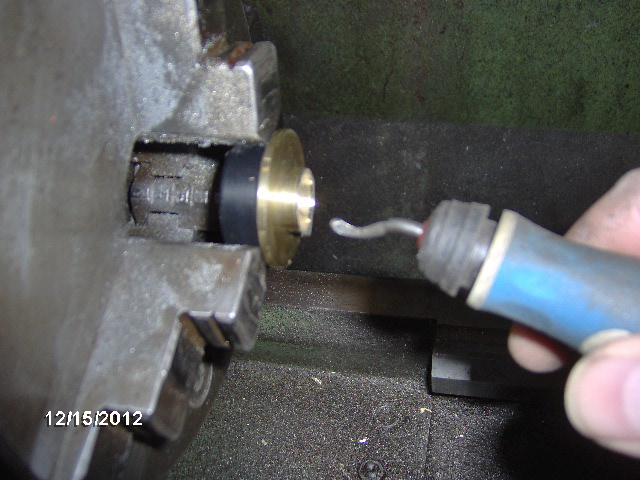

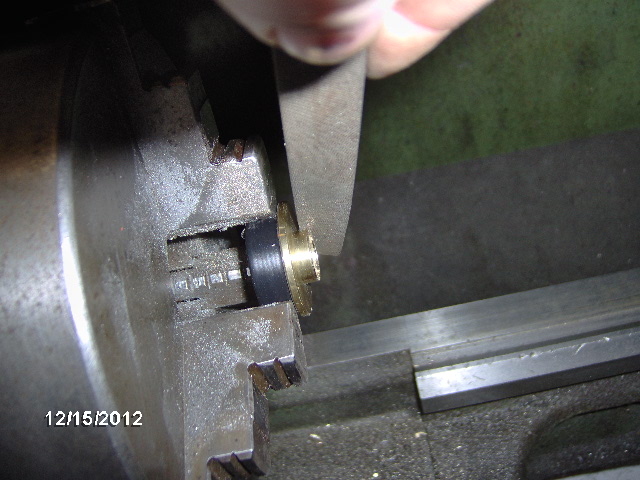

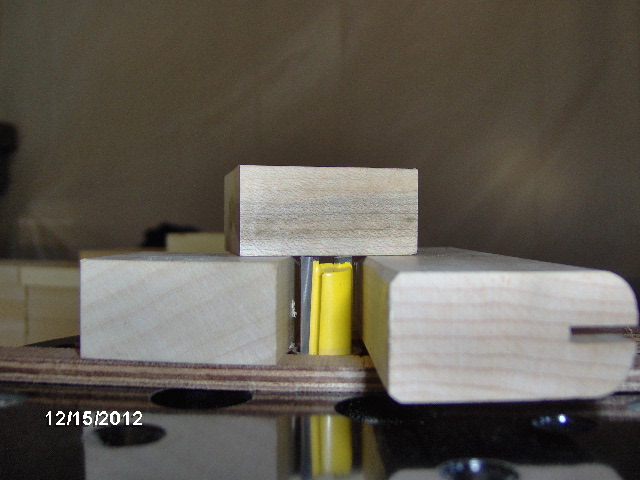

That brings us up to yesterday (Saturday). I wrapped the threads on the brass router collar with electrical tape to protect them, chucked it in the lathe and turned the end down just under the thickness of my template material.

Used the deburring tool on the inside and a fine file on the outside to remove burrs (posed photos with lathe not running for safety).

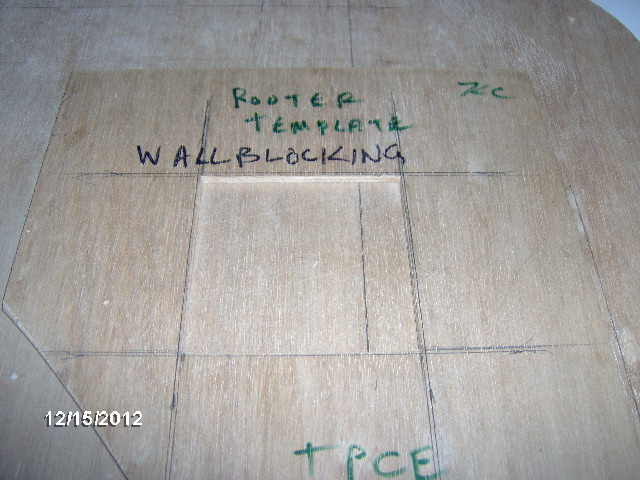

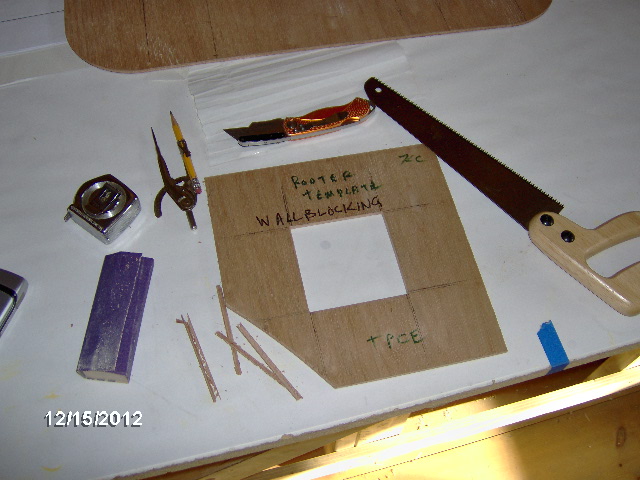

The template that I had previously made for most of the blocking was made size for size, so I had to open it up. The collar is 1/8 inch larger than the 1/2 inch bit (1/32 clearance + 1/32 thk collar per side), so I laid out lines 1/16 inch larger, used the back of my little hand saw as a straight edge, and sliced down through with a utility knife, then little clean up with the sanding block.

The compass was just used as a sharp pencil, instead of the crude carpenter’s pencil. Note the little slivers of ply in the lower left. (I have been using the drop piece from the door window template as a “desk blotter” of sorts, a cutting mat, too, but the pictures showed up better against the white table top.)

Set the router collar up and set the depth just a hair deeper than my template thickness plus 3/4 inch (1x) stock.

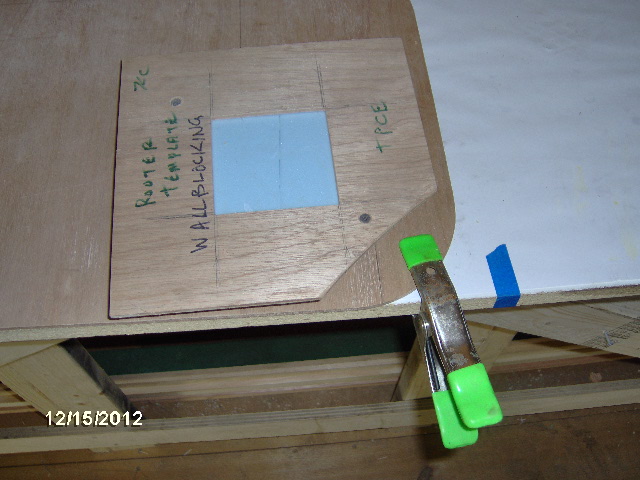

Time to do a test before touching tool to side wall. Countersunk a few holes into the template, used double side tape to stick the foam down to my blotter, clamped the blotter to the table, and hand screwed some drywall screws into the foam to secure the template.

Zipped it out easily.

Blue snow.

Used the razor knife to trim the corners of the pocket, and test fit the block.

Nice snug fit. Had to screw a couple of drywall screws into the wood in order to pull it back out again.

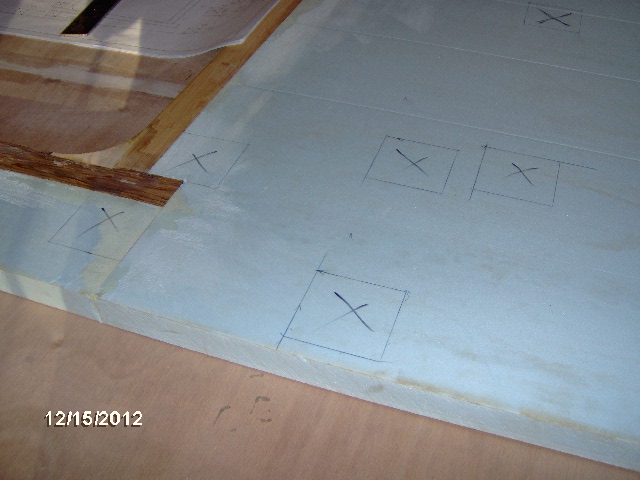

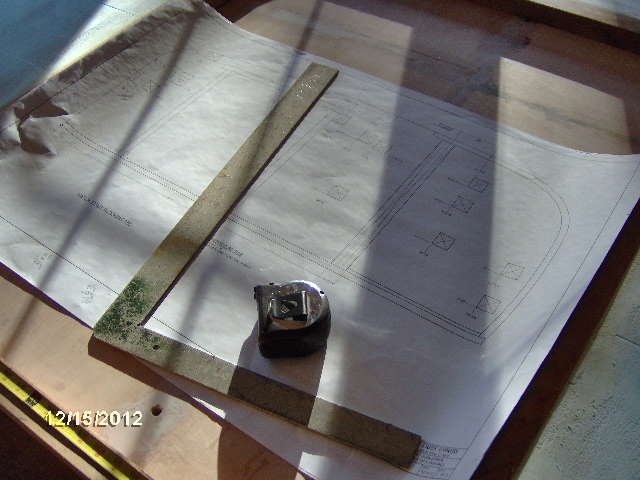

My small tape measure blew the retract spring, so I extracted the tape part, clamped it along the base line of the street side wall, and started laying out the location of (most) all of the inside wall blocking. The afternoon sun was nice, but made it difficult to get good photos.

And here is the template installed and ready to make the first pocket.

I decided that it would be much better to have a shop-vac running for dust collection before launching into all of these pockets, so decided to call it a night. Besides, I had an invite from Jeff for smoked duck at the grotto. I put the glue closer to the heater and set up a recording thermo-hygrometer over where I would like to store the glue. Karl said the morning temps had been about 40 deg F since I started the heater, and it was 61 in there by the time I left (although he was running the wood stove downstairs, which was surely contributing).

Sorry, no pic’s of the duck, but it was delicious. Soy/teriyaki marinade, a nice smoke, peppers and onions sautéed in the drippings, broccoli and fresh ginger steamed/sautéed, and a nice dark beer.

Took today off and went to get a xmas tree.

meh.

meh.

Besides , you have the place/shop to do it ,the extra time , the tools to finish it , and the Money to invest ... Why not go ALL the way ... It’s the ONLY way you’ll, be Happy !!!

Besides , you have the place/shop to do it ,the extra time , the tools to finish it , and the Money to invest ... Why not go ALL the way ... It’s the ONLY way you’ll, be Happy !!!

HUGE difference exists between the two ...

HUGE difference exists between the two ...

You see my Logic !!!

You see my Logic !!!

Just kiddin

Just kiddin