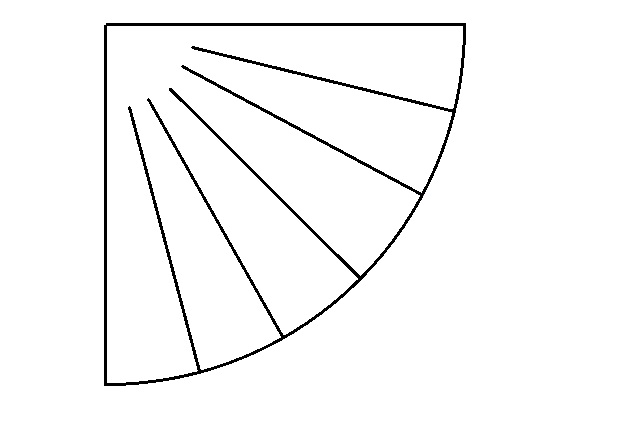

ST1100 wrote:Maybe this could be a solution for the roof corner problem.

The radius of the corners is 300 mm. So the outer length of one roof segment is 471 mm.

The square angle will be on top of the roof.

If I cut a sheet of 471 x 471 mm in this way it could lay one segment over the other like they did it at the front shell of vintage airstreams.

Then rivets and sealing with liquid from inside.

I will test it with cardboard and if that works with a sheet of aluminum.

Or better draw the lines on one eighth of a 60 cm diameter plastic ball and cut it !

Tom

Hi Tom,

If you use this method, I recommend you drill a hole at the top end of each of those

radiating lines, @ 1/16th to 1/8th inch diameter [obviously use your metric equivalents]

- or your rivet's required hole size - up by the top corner. This should prevent the metal

from ripping or cracking at that spot/point as you bend it into position and help the

top corner form a shallow cone section as you bend and form the end caps. I had to

recently fabricate a section of ductwork for an in-progress home project and this hint

helped me form the shape I needed - my first attempt at making a 3D shape from sheet metal.

Also, I was using very thin aluminum [Flashing stock, I doubled it and riveted the two

identical pieces together to get the thickness needed for at least some rigidity.] that

I cut by repeatedly scoring with an utility knife along a metal straightedge [a framing square

leg] at the cut line. I don't know if SS would allow you to do that reasonably easily or not,

but it gave me straight flush cuts with no deformation that would have been caused by

using metal shears. [I don't have access to a metal brake or guillotine style sheet metal

cutter, so I had to do it all by hand and 'by guess and by golly'.]

Cheers,

Norm/mezmo

If you have a house - you have a hobby.

Fred

Fred

Tom

Tom