GPW, Yup, and how.

ghcoe wrote:I think the gas strut looks like a better solution. Less leverage on all the lifting components.

Yup, you’re right, George. The fact that the rod end is further out closer to the CG means that the leverage is reduced, but only as the hatch approaches fully open. Although the CG moves toward the strut as the hatch closes, the angle of the force vector gets closer and closer to the hinge, actually passing it at the last moment. Since the gas pressure on the strut is constant, the leverage at this point may actually be higher than the actuator. The actuator acts on a shorter arm, but stays much closer to perpendicular to this arm throughout its travel.

Suffice to say that I plan on using a suitably robust hinge with a staggered screw hole pattern to really bed the hinge leafs solid to the double spars.

Okay, Bogo has me thinking of some options and I managed to spend a little bit of time on the model before bugging out from work due to the approaching blizzard (my department shut down at noon to allow us to get home before the worst started).

Here is a section cut through the center of both ball studs looking forward and down thru the plane of the strut in the open position. This is the same combination of parts (sockets and ball end studs) that I showed in the side geometry above, except the lower ball stud bolt face has been moved to 1/8 inch away from the side wall skin, allowing for a wall plate which is not shown (no hardwood block required between skin and anchor plate).

You can see how well the strut lines up under the hatch rib. So I decided to look at some other combinations of end types and brackets. The combination of these two parts is looking good for the top with the bracket screwed into the underside of the rib.

Eyelet BracketEyelet End FittingI think I will use hardwood for the imbedded blocks at these wall locations for the anchor plates to screw to, and I will weld a heavy SS 5/16UNC nut on the back of the plate for the

ball studs to screw into.

This just in: Above was written Friday evening before the power went out at about 8:30pm. We had about 18-20 inches of snow on top of a heavy slushy layer and it has been below freezing throughout. The power (and furnace) just came back on about an hour ago, and it is now noonish. House got down to about 41 deg F last night. Lots of blankets on the bed and three cats huddled up.

Catching up from where I left off on Friday: After getting out of work I went to the bank, had the oil changed in the Ford (I’ll do it when the weather is good, but…), and stopped at Benny’s (a five and dime) to get another gallon of white gas. They didn’t have it, but they had a combination propane lantern and hard plastic case for $30 (should have grabbed it). Stopped at another small hardware store and got the white gas. Had a pastrami Rueben for lunch, then off to Mecca to collect up the lanterns and kerosene heater, just in case.

Road to Mecca before it got bad.

Karl’s driveway.

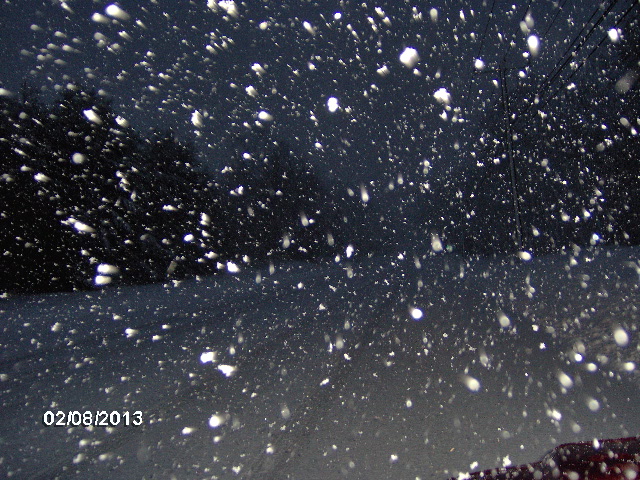

Starting to come down on the ride home.

Had to back track a little to find an open packy; this is the same location 15 min’s later.

Power went out, no cable, no internet, no land line phone.

Put the turd to work. Good call making the trip to Mecca.

Out the back of the screen porch the morning after.

This one tells the story. When I parked the Ford it was several feet up further in the driveway. It had slid down in the night to less than a foot from the tongue on the boat trailer. If it had knocked the boat off of the jack stands (unlikely) the next thing to stop it would be the outboard poking through the garage door.

Heavy snow load on the cedars, and the berm from the snow plow was about 3 ft out into the road and 2 ft high. Road still had 6 inches of snow in it, and the plow didn’t come around again until late Saturday afternoon.

I know this seems like a trifle to many of you, but this is about as big as it gets around here.

The front walk after running the snow blower for a couple of hours.

After running the blower out of the garage and up in front of the vehicles, pushing the berm across the street and doing the walks (believe me, running the blower is not effortless… horsing it around and working it into the big berms, pushing down for traction, pulling up to get it to dig down, jigging it back and forth for forward progress) I went in for some hot oatmeal and a hot cup of tea while Yvette chipped up the packed layer and started to uncover the vehicles so that we could pull them out and get the rest.

Did absolutely nothing to the 413E that I got from MaureenM, except put fuel in and pump. Great working stove.

The 228E Big Hat takes a turn at lighting duties Saturday night.

It is now Sunday mid day and the furnace is playing catch-up. I had to switch off the circuit for the hardwired radon blower because when it came back on it was droning something fierce. The exhaust chimney that exits up the side of the house near the rain gutter must be choked with snow.

All for now; I am staying under this blanket until the heat comes up.

)

) no bias here. the male really does look good, but the female, well hubby keeps saying she looks like she belongs in the wild. she has some weird looking fur, real wavy. but gotta love her anyways.

no bias here. the male really does look good, but the female, well hubby keeps saying she looks like she belongs in the wild. she has some weird looking fur, real wavy. but gotta love her anyways.

Any reason why?

Any reason why?  More work to do !!!

More work to do !!!

.

.