Glue? How to attach aluminum skins....

13 posts

• Page 1 of 1

Glue? How to attach aluminum skins....

Working with a supplier for all of my teardrop parts....I am curious about attaching the aluminum skins (using .063 to the sides, and .040 for the top) to the 3/4" Baltic Birch sides. Supplier says to let them "float" with just the aluminum extruded trim holding them on, but I've seen some say that you should glue them down. Now, I am really concerned about the difference in which the aluminum will expand/contract vs. the 3/4" birch......what do you guys think? I plan to post some pics of the progress so far soon!

- geocachenut

- Teardrop Inspector

- Posts: 14

- Joined: Tue Sep 04, 2012 8:25 pm

Re: Glue? How to attach aluminum skins....

This question will get you almost as many different answers as asking what your favorite teardrop design is.

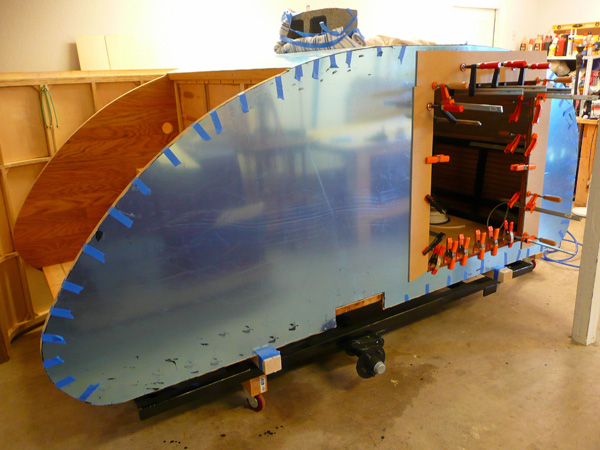

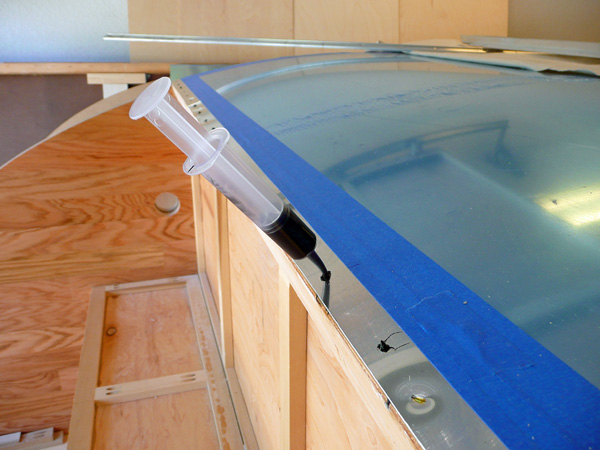

I'm in the "float" camp but used sealant/adhesive around the perimeter and at all openings along with the trim to keep the aluminum attached. The exterior trim was bedded in sealant too. All screw and fastener holes were pre-drilled, sealant was injected into the holes, and then the screws/fasteners were put in place. Here's a few photos:

There is some minor oil-canning in the aluminum in the extreme heat of the summer, but I feel that is better than having the aluminum expand and try to separate from being directly bonded to the plywood.

Take care,

Tom

I'm in the "float" camp but used sealant/adhesive around the perimeter and at all openings along with the trim to keep the aluminum attached. The exterior trim was bedded in sealant too. All screw and fastener holes were pre-drilled, sealant was injected into the holes, and then the screws/fasteners were put in place. Here's a few photos:

There is some minor oil-canning in the aluminum in the extreme heat of the summer, but I feel that is better than having the aluminum expand and try to separate from being directly bonded to the plywood.

Take care,

Tom

Last edited by aggie79 on Mon Mar 04, 2013 5:32 pm, edited 1 time in total.

-

aggie79 - Super Duper Lifetime Member

- Posts: 5405

- Images: 686

- Joined: Tue Aug 07, 2007 5:42 pm

- Location: Watauga, Texas

Danny

Danny