I'm getting ready to build my doors, and was going to make them out of pine and hardwood boards, using sandwich type construction, the same as the sides. After cutting the ribs for my hatch out of a sheet of 3/4" 9 ply baltic birch plywood, I noticed that I have enough scrap left to make the doors.

I know that normally it is not a good idea to put screws into the edges of plywood, since they don't usually hold well, but was wondering if the 9 ply baltic birch was strong enough. I already ordered stainless steel piano hinges (should be here Monday), so I really don't want to change my plan and use the ones with the angle on them that are designed for plywood, since I would have to wait a couple of more weeks for them to arrive, not to mention, I have already purchased the others.

The 3/4" baltic birch plywood would be one piece, covered on the inside with 1/4" birch plywood, and on the outside with 1/4" laun, then aluminum, to match the side walls. I would cut voids in the 3/4" to lighten it up, and add insulation.

Would I be better off gluing a 1" strip of hardwood to the hinge side for the screws to go into, or possibly drill larger holes in the 3/4" , and glue dowels in where the screws will go?

Or, should I just go back to my original way, and make the frame for the door out of 3/4" pine, with the edge that the hinge screws into made of hardwood?

The reason I want to use the 3/4" baltic birch, is that I think it will stay flat, where if I glue up a frame out of pine and hardwood boards, there is a pretty good chance it will warp (not to mention, I have the birch already).

Door Question

9 posts

• Page 1 of 1

Door Question

Jeff & Odie

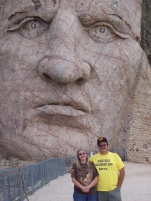

Black Hills of South Dakota

Black Hills of South Dakota

-

JunkMan - 500 Club

- Posts: 974

- Images: 50

- Joined: Sun Oct 24, 2004 6:21 pm

- Location: Rapid City, South Dakota

Jeff,

9-ply Baltic Birch will hold a screw in the edge better than any other of the "stacked" woods, but it's still a "stacked wood". So it depends on how much real holding power you're asking for.

9-ply Baltic Birch will hold a screw in the edge better than any other of the "stacked" woods, but it's still a "stacked wood". So it depends on how much real holding power you're asking for.

Chris

The tension between what is good enough and what is beyond that creates the space for character to become our work.

Teardrop Trailer Build Pictures: http://tinyurl.com/px5cd

The tension between what is good enough and what is beyond that creates the space for character to become our work.

Teardrop Trailer Build Pictures: http://tinyurl.com/px5cd

- Chris C

- .

- Posts: 3302

- Joined: Sun May 15, 2005 7:24 pm

- Location: Norman, Oklahoma