danlott wrote:Always great to see a new trolley top "Molly Croft Roof" idea. Will be watching your build progress.

Dan

Cheers Hope it works out in real life the way it's working in my head.

danlott wrote:Always great to see a new trolley top "Molly Croft Roof" idea. Will be watching your build progress.

Dan

donal94 wrote:Are the 4mm sheets from goodwins I can't see them for €8

mezmo wrote:The MollyCroft/TrolleyTop approach is a very creative way

to deal with your conflicting trailer and sheet goods dimensions.

I'm sure you'll be happy with the design when it's completed.

I've often wondered if building each 'side' of the trailer body,

like mirrored cabinets [including the MolleyCroft side beams],

and then joining them together later with the center section/roof,

would be a good approach.

And the MollyCroft idea could be carried further to have the center

section go from the front wall base over to the rear bumper...

Cheers,

Norm/mezmo

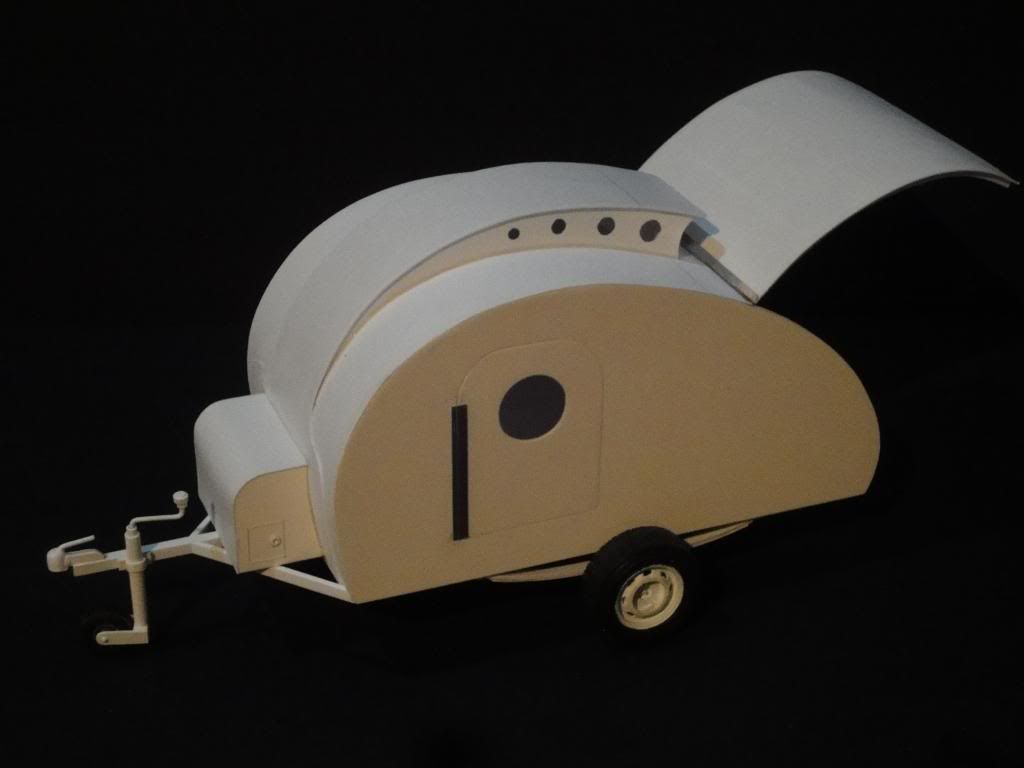

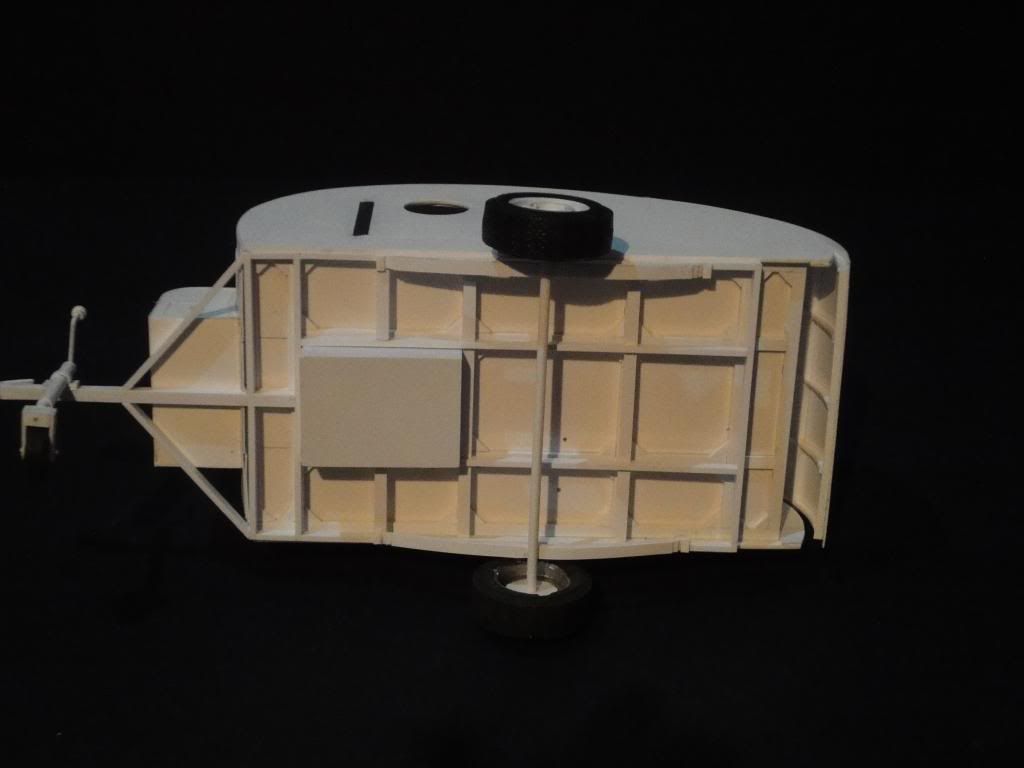

KCStudly wrote:Wow, that is a seriously detailed model!

Is it scratch built or did you start with some sort of kit for the jack wheel, hitch, etc.? Maybe a 3D printer?

If a kit, which one? If not, and hand built, WOW! Great detail.

I noticed that the leaf springs are really long (which should yield a nice soft ride). Is that to your plan, or...?

Nice model.

KCStudly wrote:It was a compliment of the highest order, the fact that you, a true craftsman, can make something so time consuming for us mere mortals to even consider,and so exacting.

Sweet.

Mind if I ask what business you are in making models? I am impressed.

I'd be reluctant to try to squash the insulation. The pressure inside your structure may loosen the wall up.

I'd be reluctant to try to squash the insulation. The pressure inside your structure may loosen the wall up.

Users browsing this forum: No registered users and 17 guests