trail dog?

and thanks for the durability answers. I don't see me needing the whole kit, but an easy way to make the hatch would be great!

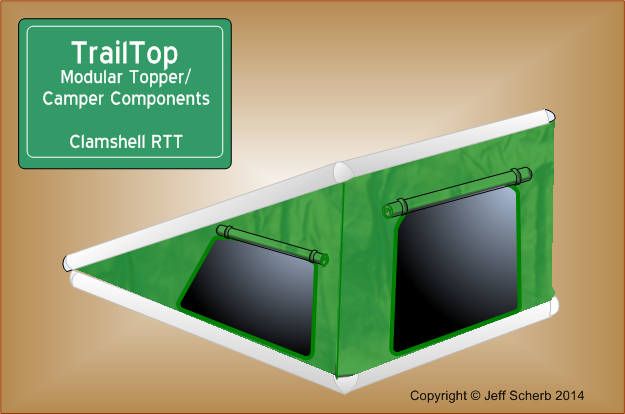

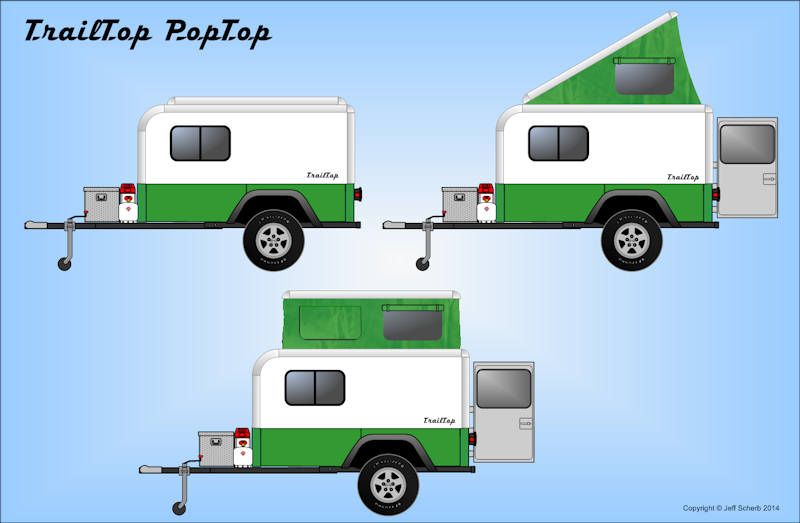

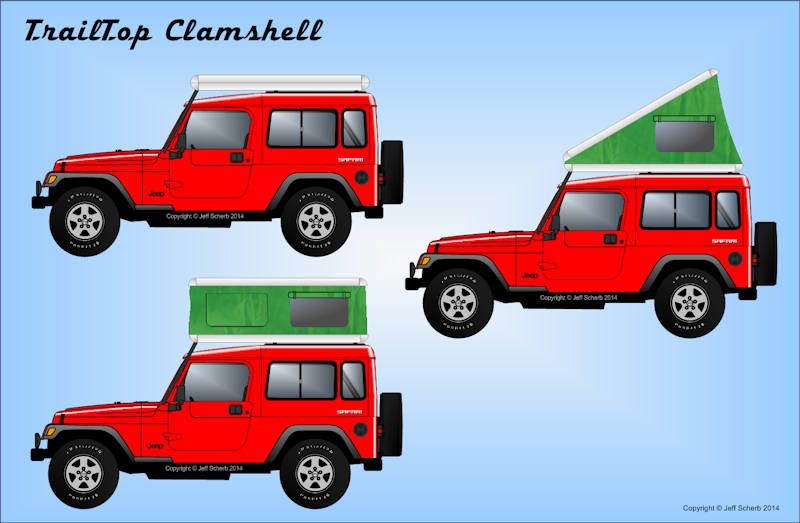

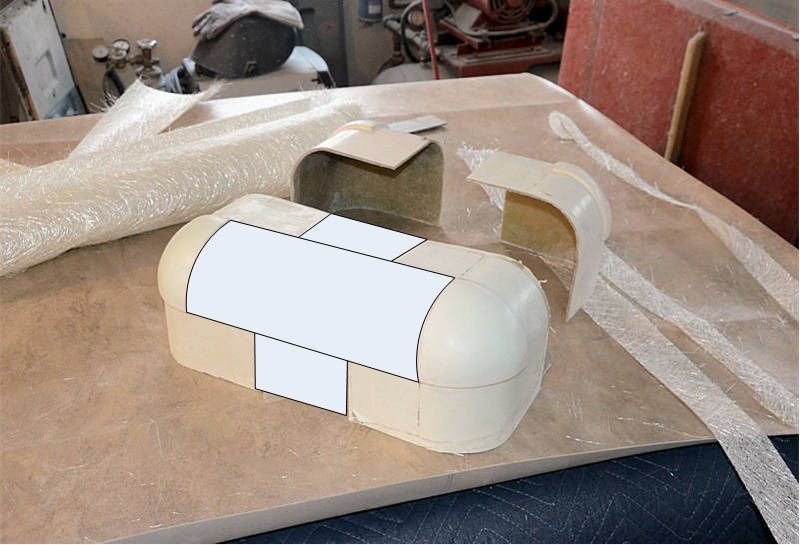

"TrailTop" modular trailer building components

-

rowerwet - Gold Donating Member

- Posts: 2075

- Images: 521

- Joined: Mon Apr 20, 2009 12:52 am

- Location: Merrimack River Valley

Re: "TrailTop" modular trailer building components

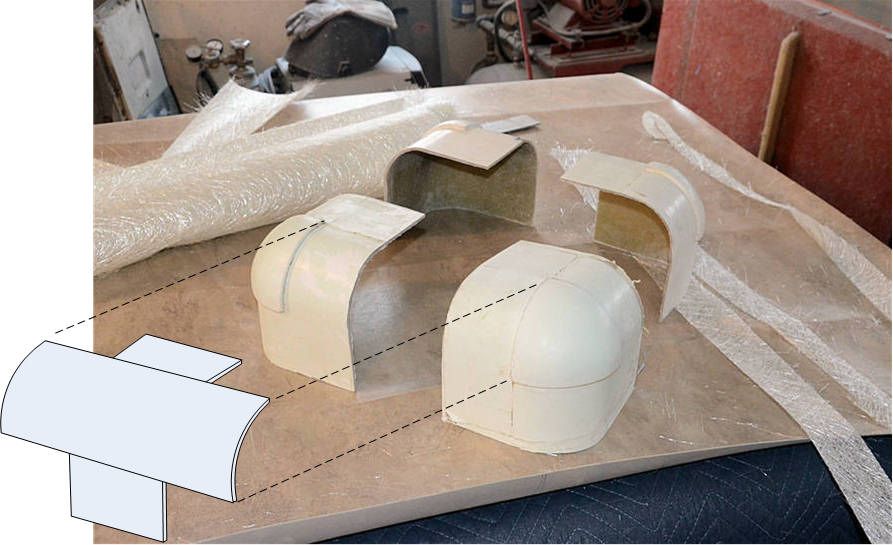

How is the seam made between the curved panels and the ply? If both the plywood and the curved panels rest on the flanges of the corner pieces, doesn't that mean the the cut curved panels butt to the ply? If correct, I assume that there is a batten backing each of these joints.

KC

My Build: The Poet Creek Express Hybrid Foamie

Poet Creek Or Bust

Engineering the TLAR way - "That Looks About Right"

TnTTT ORIGINAL 200A LANTERN CLUB = "The 200A Gang"

Green Lantern Corpsmen

My Build: The Poet Creek Express Hybrid Foamie

Poet Creek Or Bust

Engineering the TLAR way - "That Looks About Right"

TnTTT ORIGINAL 200A LANTERN CLUB = "The 200A Gang"

Green Lantern Corpsmen

-

KCStudly - Donating Member

- Posts: 9640

- Images: 8169

- Joined: Mon Feb 06, 2012 10:18 pm

- Location: Southeastern CT, USA

.

. ."

."