I guess I’ve been slacking off some lately. It seems that I haven’t been putting in as much time each session and I haven’t been getting as much done. It seems to be a trend as I approach slightly (?) daunting tasks. I slow down and try to think things through so that I don’t steam roll myself into trouble. By default it gives me a chance to focus on little details as I work on the lesser things at hand, while I imagine how I will handle things on the next big task.

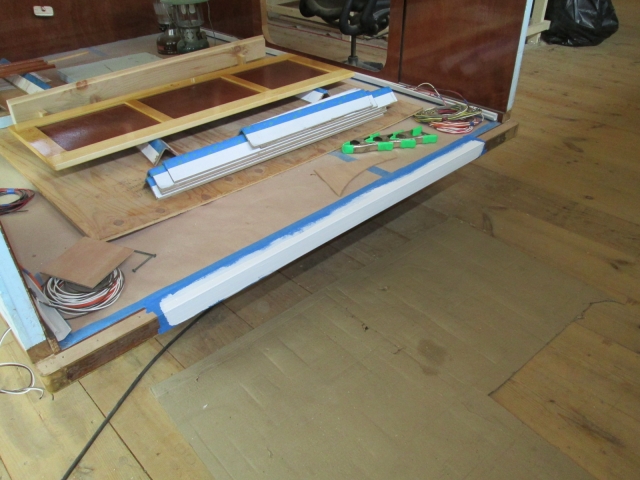

So in the not too distant future I will be assembling all of these front wall parts and sticking the assembly on the front of the cabin. A few things come to mind that might be important: what order to assemble; where and how to mask so I don’t get glue all over the nice finishes; and how best to attach the front wall skin to the edges of the walls where there is no blocking or shelf ledgers to screw to (I’m considering using long drywall screws directly into the foam, but haven’t decided which type of glue to use).

Anyway, I’m creeping up on it.

Friday I was asked to stay late at work and help repair a piece of machinery with a failed mechanical seal, which ran late, so no progress.

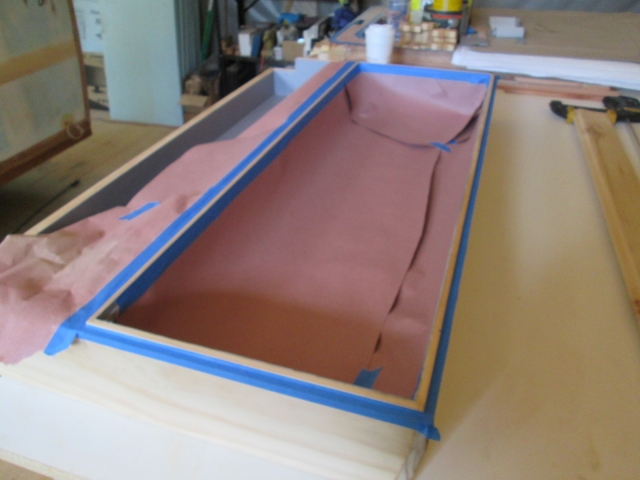

Saturday I made a little progress on the locker details. Where I had overlapped the corners of the vinyl at the top, I had forgotten to trim the underlying layer to clear the hinge location, and by chance the flap would have made the hinge cockeyed. So I peeled up each corner, trimmed the underlying flap, found the hinge screw holes and glued the outer layer back down. You can see the difference in the lumps of the corner tabs printing through after trimming.

Here it is with the hinge mocked into place so you can see how the hinge only sits on one layer of vinyl now.

I used prior measurements and a piece of dowel sanded to a dull point to poke around and find the screw holes for the divider shelf ledgers; poked thru the vinyl with the tip of my compass, and screwed the ledgers in place with the divider bar.

I started to make some adjustments to the divider shelf so that it would fit with the addition of the vinyl. Trimmed the length and shaved the back some with the small matchbox plane, but I ended up chipping out a piece on the corner. I suppose I should have kept going and got it to fit, then glued the chip back into place, but I didn’t think that thru too well and stopped to glue it up. Here it is, later, all better.

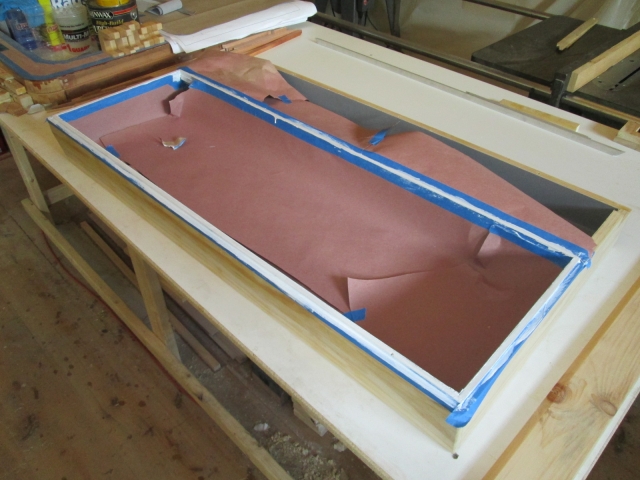

In hindsight it would have been better to keep fitting the divider because the next move was to mask off the locker case so that I could paint the rabbet edge. With the case masked, after the divider glue was set, I couldn’t go back to fitting it, and I would have liked to have included it in the painting process. Oh well, I’ll get to it later. Here is the case first masked then primed, including the little area on the sill that needed to be touched up.

Cut work short on Saturday to go see the

Charles W. Morgan in New London. Bill (of mom and Bill) has been volunteering at the Mystic Seaport for some time and has worked on the restoration of this, the oldest commercial sailing vessel in the US. Mystic is historically significant for its shipbuilding, and New London for its whaling history. As the restoration of the Morgan nears completion, they moved it out of the shallow Mystic River over to the Thames River (which is much deeper due to being dredged for the submarine traffic) to the state pier so that they could load the remaining ballast. This is the first time since (IIRC) 1941 that the ship has been out of the Mystic. After final preparation the Morgan will sail under her own power on a tour of ports here in New England (including a visit to the USS Constitution in Boston), before returning to the Seaport.

Anyway, I took some pictures that I thought you all might enjoy.

Whale tail fountain, New London, CT.

Historic Bank St., downtown New London.

The Morgan.

The main mast and rigging.

The foredeck.

Today I just spent a couple of hours getting some more of the primer down.

Scraped some poly drips off the front of the front wall skin and masked the area that will end up being inside of the locker well.

Then primer.

Put a second coat on the front edge of the floor.

A 2nd coat on the lip of the locker case.

And while I was at it, a 2nd coat on the front toe kick spar in way of the locker.

This morning Yvette had dropped an earring down the sink drain and I had pulled the trap out to retrieve it. I stopped at the hardware to get a fresh trap gasket and wanted to get home early to complete the repair (and watch the drags from Old Bridge Township!), so it was a short day.

They have self driving cars now , why not self-cleaning ? Black vehicles (as Randy G knows ) here are good for baking cookies in ...

They have self driving cars now , why not self-cleaning ? Black vehicles (as Randy G knows ) here are good for baking cookies in ...  I had a black van once , a real monster to keep clean , and I leaned on it once in the mid summer sun and got 3rd degree burns ...

I had a black van once , a real monster to keep clean , and I leaned on it once in the mid summer sun and got 3rd degree burns ...

They have self driving cars now , why not self-cleaning ? Black vehicles (as Randy G knows ) here are good for baking cookies in ...

They have self driving cars now , why not self-cleaning ? Black vehicles (as Randy G knows ) here are good for baking cookies in ...  I had a black van once , a real monster to keep clean , and I leaned on it once in the mid summer sun and got 3rd degree burns ...

I had a black van once , a real monster to keep clean , and I leaned on it once in the mid summer sun and got 3rd degree burns ...

... All I can say anymore is WOW !!! ... and drool ...

... All I can say anymore is WOW !!! ... and drool ...