Hmm, not sure what to think about that. I think it is comparable to any other random first time build. Some get a lot of attention to design and details and come out really nice, though take a long time. Some go together quickly, but may not be as well finished or have as many features, like a simple plywood floor instead of an insulated built up one. Only a very few well experienced builders are able to have the best of it all with a high degree of craftsmanship, fit and finish, and lots of custom touches in a short build time. Not me. Oh well.

I think there are a few things that are contributing to the time factor on this build. First and foremost is probably my nature. I sweat the details and try to work to a high level of accuracy.

Secondly, the wood finishing and the fact that I chose to use contrasting stains and wood species; light Maple and dark Okoume. Keeping these two separate and the extra effort to mask glue areas during finishing and assembly has been very tedious and time consuming work, but I love the results! A single color of paint applied after assembly would have been so much easier and quicker.

Third, I sure do recall becoming extremely bored with the tedium of installing all of the wood blocking that was let into the foam. Despite doing several at a time, it seemed like that phase went on forever.

Lastly, I would say that the special features that I am incorporating have taken more time than a basic build; things like the front locker, battery box built into the TB, the flush mount windows in the homemade doors, and, I guess, these external tool mounts.

Like I have said before, I probably have more time and gas money into my daily commute to Mecca than most people have in their whole build!

Today I continued with the blocking for the shovel and axe mounting brackets. I used the milling machine to counterbore (7/8 inch Forstner) and drill (3/8 inch) for the 5/16-18UNC thread inserts. Here you can see some of the counterbores and some with inserts installed. These are the backs of the outer layer of the 4 different blocks. (The wood is a little rag-tag with some extra screw holes as it was formerly used as a router template.)

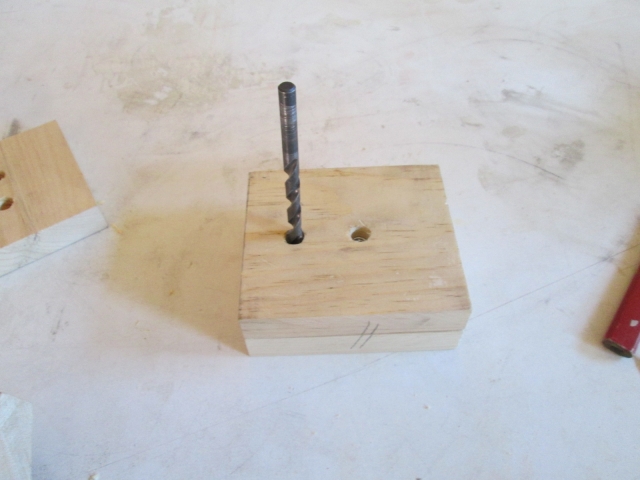

Before gluing to the second piece I lined them each up and used a close fitting drill bit to transfer the centers of the thread inserts. Note the match marks on the edges in the first pic and the bit marks circled in the second.

Next I used a 3/8 inch Forstner bit to drill part way thru the second block providing a place for the tips of the bolts to stick thru. Used the little stick with pencil mark as a dip stick to creep up on the desired depth.

In my twisted way of over complicating things, my logic is that it will be easier to seal and isolate these penetrations from the rest of the front wall by keeping these holes blind. The plan is to saturate the holes with “the mix” after gluing the blocks together.

I used PL to glue the assemblies and clamped them to an out of the way corner of the bench.

I did a quickie sanding job on the TB spackle with 220 grit, but forgot the tub of spackle at home, so was unable to apply a second round.

Next I laid out the location of the blocking for the shovel handle mount. The spade on the shovel is only slightly narrower than the space between the side wall and side of the locker bump out, so I took special care to center the mount so the spade won’t interfere with the lid on the TB when it is tipped back.

I used the steak knife to slice around the perimeter and was happy that the piece seemed well attached and didn’t want to just fall out. I figured I would have to work at it with a chisel, but after just three stabs and a couple of hits with the mallet the whole piece popped out.

There was glue on the wood and glue on the foam, but no sign of foam being torn. Not sure if that means I didn’t have good clamping force, or what. These lower front areas will be captured under the rock guards, so there is no need to worry or rip them out, but I will definitely be using different glue for the rest of the foam.

I ended the session by disassembling the brown Moonlighter kerosene heater and pulling the wick out; time for a new one.

).

).