how to figure the best spot to start the gallay hatch

5 posts

• Page 1 of 1

how to figure the best spot to start the gallay hatch

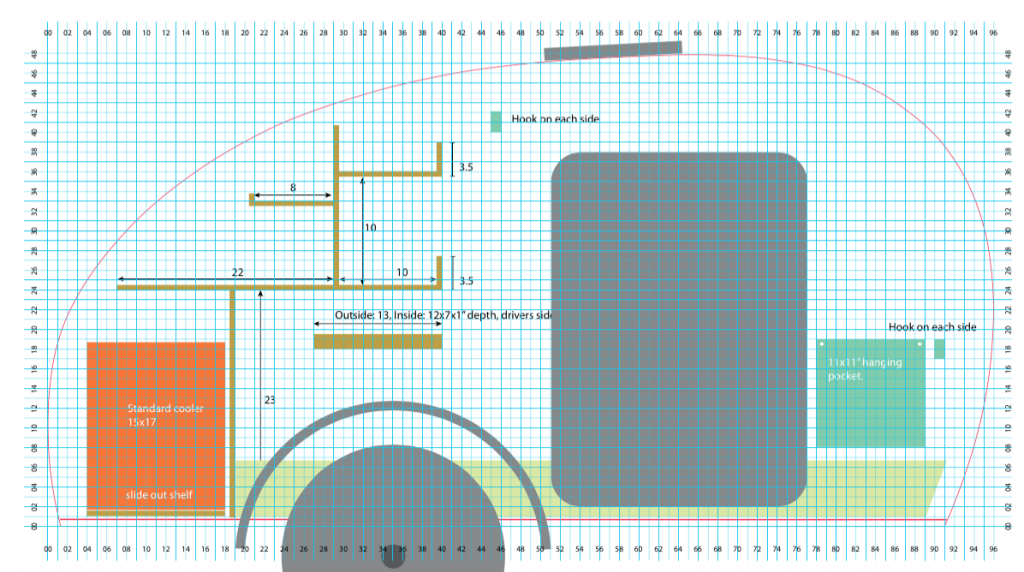

I'm building 5 x 10 x 4ft benroy of sorts working on design I looked a atleast a thousand different teardrop pictures online but never seen one in person, looking for input on where to start the galley hatch there will be a bunkhead installed 82" back from the front which I'm thinking the roof will be flat at that point, which installing the hinge on the flat part of the roof could be bad news or is that ok? also I see some teardrop where the galley hatch stops at counter height, is there a disadvantage to stopping there other then losing drawer space, I keep think it may be nice to have the hatch go all the way to the floor just to give you more roof over your head with the hatch open, I guess im looking for a rule of thumb about sizing the rear hatch the more I Iook at them I like a TC Teardrop profile but maybe bring the hatch all the way to the floor, any input would be great

- ibbowhunting

- Teardrop Advisor

- Posts: 65

- Joined: Sun Mar 22, 2015 12:12 pm

Re: how to figure the best spot to start the gallay hatch

I say bring it to the floor. My galley hinge point is about 5" in front of the upper bulkhead/ inside cabinet back wall.

My first build, so I really don't know if there is a rule of thumb.

My first build, so I really don't know if there is a rule of thumb.

Kaz

-

Kaz - Silver Donating Member

- Posts: 229

- Images: 122

- Joined: Tue Sep 23, 2014 3:27 pm

- Location: Hanson. MA