Sill in the design/thinking stage. Trying to work out a design.

I am looking at peoples' various designs and design discussions and noticed that many of the designs are using circular rather than elliptical curves.

The classic Grumman has elliptical lines.

Is there some technical reason to use circular curves other than easier to cut ie a single pivot. I have found in the wood working sites an elliptical cutting jig which appears to make the task fairly straight forward.

Is it harder to bend plywood along an elliptical edge? It looks like it would be easier except as you approach the crossing of the major axis.

Is it harder to build a hatch that is elliptical ? Or if the hatch spans steepest part of the curve ( where the major axis joins the curve )

Is it harder to get the two roof curves ie the inner roof line and outer roof line assuming you have a template with each curves (two templates).

On a related topic, what thickness of plywood can be easily bent without any cutting. It appears 1/8" works well. Can the same be said for 1/4" ply?

Are there curves that are too small? Obviously very small (3" radius) would be extremely difficult/impossible. But where is the break even point ie 10", 15", 20" ? I suppose one could try them out, but that could be pretty extensive/expensive building so many tests.

Ellipticle Curves vs Circular Curves

9 posts

• Page 1 of 1

Ellipticle Curves vs Circular Curves

Michael Krolewski

Scottish Terrier Fancier

Scottish Terrier Fancier

- troubleScottie

- Donating Member

- Posts: 360

- Images: 16

- Joined: Sat Apr 11, 2015 5:02 am

- Location: Seattle, WA

Re: Ellipticle Curves vs Circular Curves

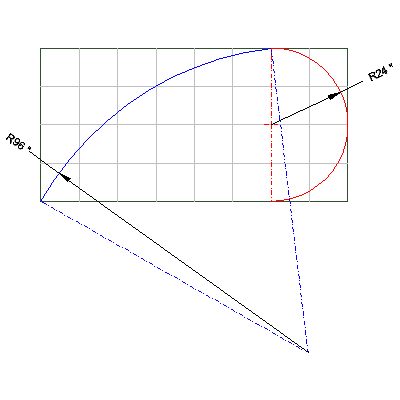

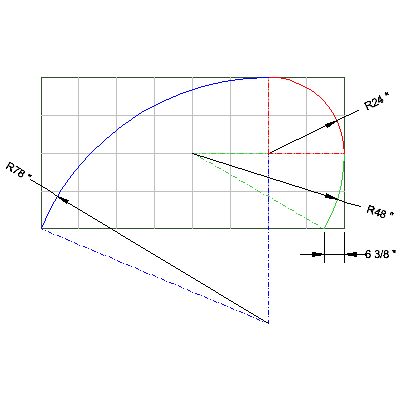

Here are some real early in my build discussions on the same topic.....

http://tnttt.com/viewtopic.php?f=27&t=13925&p=181475#p181475

Looks like the images didn't survive a couple of crashes.

Luckily I had them tucked away

http://tnttt.com/viewtopic.php?f=27&t=13925&p=181475#p181475

Looks like the images didn't survive a couple of crashes.

Luckily I had them tucked away

Growing older but not up !

-

bobhenry - Ten Grand Club

- Posts: 10368

- Images: 2623

- Joined: Fri Feb 09, 2007 7:49 am

- Location: INDIANA, LINDEN