It looks like this is the same

spec sheet that was formerly available from Spal, for my 10 inch throw actuators, probably contract label from the OEM for their brand, and now offered by Creative Werks.

This

robotics website appears to have a ready made controller that will do what I want (…and is probably the same unit found on other branded sites).

Here is the instruction pamphlet with diagram. Unfortunately the control pod is not weather proof, but it looks like I can use my marine rocker switch as the optional control input.

Others may be interested in

LearnRobotGeek.com Arduino DIY controller for single actuator, but that won't work for my app. I'm sure there must also be synchronizer versions out there, but I didn't bother to continue looking.

In other news it seems that I have not been very productive lately, and I would like to kick it into gear and get going like the “good old days”.

Take this evening for example. I worked later than usual at the day job; did my usual after punch out wind down checking in on the forum; got to Mecca at about 5:30pm; gabbed with Karl for maybe 45 min; worked for another hour trying to dry fit the middle foam panel (first layer) on the hatch using tape (failed tape 101 miserably… the blue tape doesn’t hold the load and, with no dispenser, I fumbled around with the packing tape) intermingled with about 15min helping Karl maneuver a twin axle dump truck into the shop for some fab work.

Also, I picked up a mount for the camera and have been experimenting with my new 256GB HD SD card, taking action vids from the Ford (learning the ins and outs so that I can document the trip on the Magruder) and trying out some construction scenes so I am ready when the grand lowering happens. Nothing worthy yet, just diddling. Here is the mount I got from Best Buy.

The flex stem and clamp have the std. 1/4-20 thread, and a Go Pro adapter was included (the 1/4-20 female to 3-wing hinge like dealie-o). When I mentioned that my camera was not a Go Pro the sales rep at the store pulled the last piece (2-wing to male 1/4-20 with thumb wheel lock) from a drawer at their kiosk and said it was gratis. Apparently the Go Pro mounts use this proprietary mount with a special bolt that acts like a hinge and clamps the leaves of the hinge (the wings) all in one. Turns out to be a standard 5mm metric thread, so I grabbed a 5mm socket head cylindrical cap screw, trimmed it to length and added the little press-on thumb wheel adapter, providing another 2 degrees of freedom (tilt and pan).

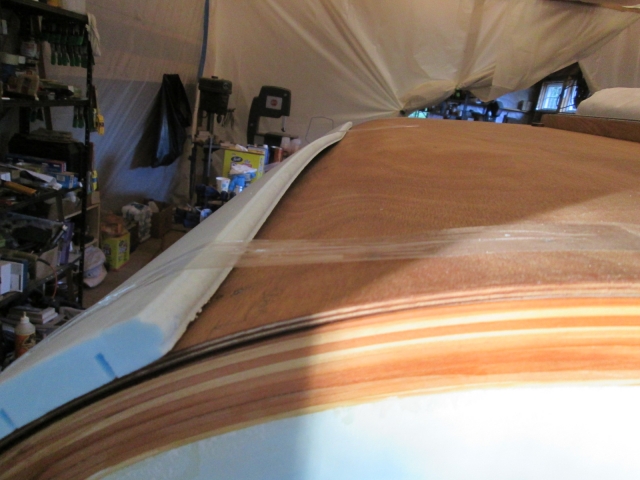

Not having much luck with the tape, I pinned the bottom of the middle panel to the top of the lower panels using bamboo skewers.

By comparison, the tape at the top was marginal at best.

Because the skewers were at such an acute angle I was able to lay the stretcher down over them without drama. However, for some reason I had a hard time getting the clamps to toe onto the small lip of the bumper, as before. Decided I needed to get a couple more 2x3’s to use as a temporary cleat under the bumper. Hit the HW store on the way home so I won’t forget them tomorrow.

As Sheddie suggested, the idea of side clearance lights, and even fender marker lights is growing on me, and I am formulating a scheme that will allow me to add the wire ways (hopefully) with little drama, good serviceability, and relative ease of fairing so that they don’t end up projecting thru the outer canvas skin.