Help Trailer wiring 7-pin

15 posts

• Page 1 of 1

Help Trailer wiring 7-pin

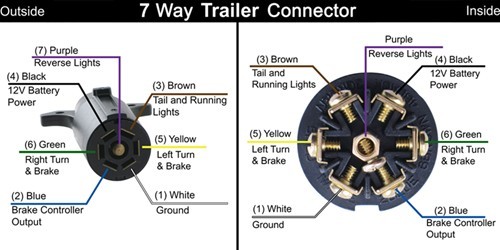

So I'm working on the trailer wiring and I have looked at a few schamtics and I can't really tell how the lights themselves are grounded I wanted some input from you guys on how you've done it ie. Independent grounds or a group ground for all the light I'll attach a diagram of how I plan on doing mine.

-

JmsCaverly - Teardrop Master

- Posts: 150

- Images: 175

- Joined: Mon Jul 20, 2015 4:32 pm

- Location: Travis AFB

Re: Help Trailer wiring 7-pin

,,...

Last edited by H.A. on Wed Feb 03, 2016 9:01 pm, edited 1 time in total.

- H.A.

- The 300 Club

- Posts: 461

- Images: 0

- Joined: Tue Nov 15, 2011 8:16 pm