I'll throw in my 2 cents here. Caveat: I haven't built my trailer yet! So I speak not from any trailer specific experience, but from having studied heat transfer in school, designed wall assemblies at work with thermal bridging in mind (I'm an HVAC engineer), and having thought about my trailer a lot. Insulation and overall thermal performance is something I enjoy nerding out about in general.

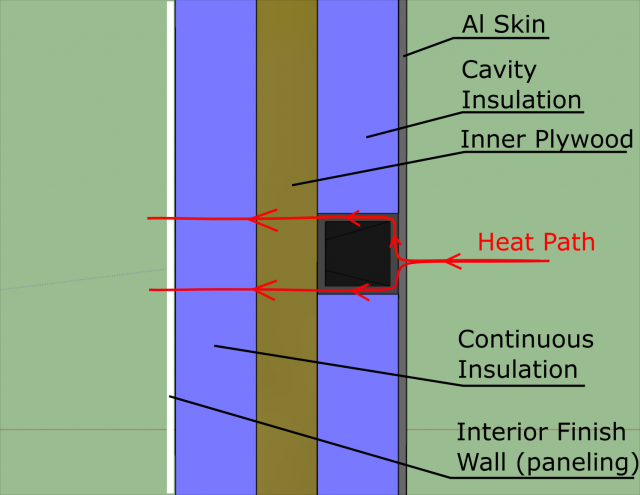

Here's a diagram of how I plan on doing my wall for my CTC:

In English: I will install rigid foam insulation in the cavities in between the 1" frame tubing.

Then the original 1/2" plywood will go back on.

And then I will fasten another 1" of *continuous* rigid foam insulation over that plywood. Continuous is a term used in the building industry to imply that the insulation is not thermally broken by studs or anything else.

To my mind, continuous insulation is the only effective way of combating the significant thermal bridging that you have with aluminum framing.

Also, a note about foam insulation on the inside of the tubing: it is my respectful belief, based not on experience but on, well, math, that adding foam insulation to the inside of metal tubing would have almost zero mitigating effect on thermal bridging.

The red lines in my image show the path that heat is most going to want to take. It is going to "want" to go from the Al skin, to the tubing, to the plywood, and then on to the inside. The heat will not want to go through the dead air space in the middle of the tubing, it is going to want to flow from metal surface to metal surface. Air, when it isn't moving, is actually a pretty good insulator. And inside a 1" tube, it doesn't have enough room to move and set up convective currents, so a 1" Al tube is effectively already insulated inside. (Sort of like a really skinny double-pane window...)

fourbtgait wrote:3m VHB tape to attach the outer skin to the tubing instead of screws/rivets.

No insulation factor but will help cut down direct transfer.

I would think this would help, have been thinking about doing something similar with my floor assembly. (Maybe some sort of thick thermal tape as well as screws though... I'd be worried about the lack of mechanical fastening?)