That floor to wall join ...

Moderator: eaglesdare

57 posts

• Page 2 of 4 • 1, 2, 3, 4

If I were building a foamie my wall to floor attachment would be is this. I would either inset a piece of quarter inch plywood along the the length of the floor attachment on the inside or skin the whole inside with quarter inch birch. Then on the outside I would also inset a half inch thick piece of wood the whole length of the floor attachment area. All glued in with gorilla glue this would spread the clamping pressure over a wider area of the foam .

Scott

Scott

- IASCOTT

- Teardrop Advisor

- Posts: 65

- Images: 9

- Joined: Mon Jul 17, 2006 1:13 am

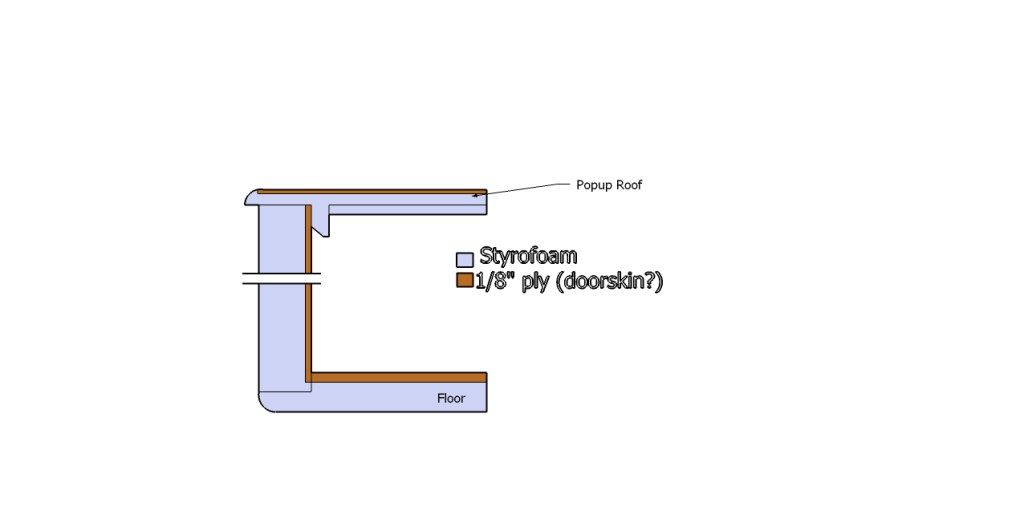

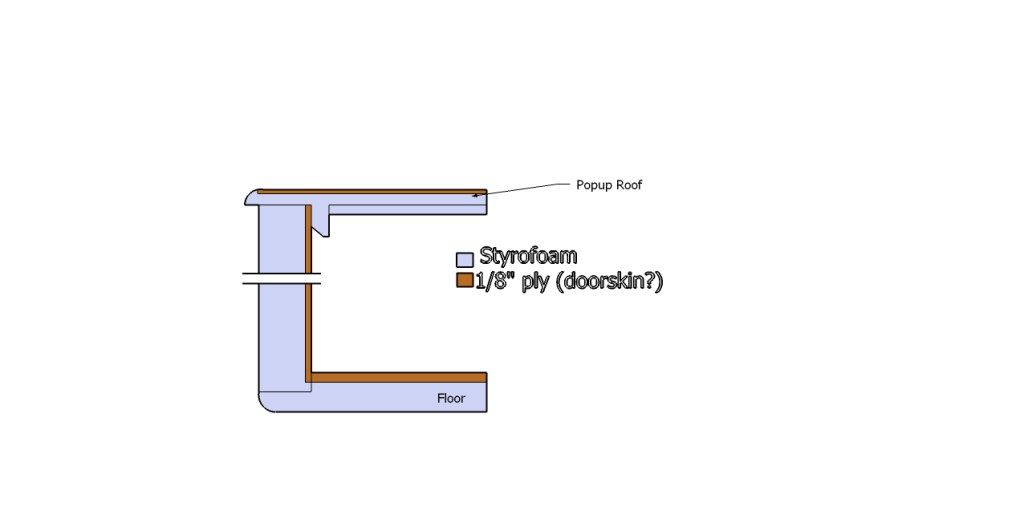

FWIW, this is how I plan on doing my floor-wall joint. It will be sheathed in glass on the outside and tabbed corners on the inside.

It's also my first shot at figuring out SketchUp.

Is that a good drawing program for occasional use ?

Since I'm at the start of the learning curve, it'll be easier to switch now...

It's also my first shot at figuring out SketchUp.

Is that a good drawing program for occasional use ?

Since I'm at the start of the learning curve, it'll be easier to switch now...

-

Wobbly Wheels - Donating Member

- Posts: 1080

- Joined: Tue Mar 15, 2011 9:51 am

3/4' ply floor has worked well so far for so many ...

3/4' ply floor has worked well so far for so many ...