I had received a call from Rob at RW Trailer Parts (in Linthicum, MD) earlier in the week that my new axle had come in, so as soon as we were awake and in our clothes yesterday morning we were out the door and on our way to pick it up.

The axle is a Dexter Torflex #9 torsion axle with EZ-Lube hubs, 5 on 4.5" bolt pattern, 10 degree drop on the arms, rubber rated at 1200# and brake flanges (but no brakes).

With the down angle and the larger wheels/tires the trailer sits perfectly level behind the Jeep now. If I ever need to pull the trailer with my Hyundai I will just use a draw bar with a bit of a rise.

I was considering getting electric brakes for the trailer, but after talking to the distributor he actually talked me out of it. He said that the small (7") brakes that they use on that small axle don't have much power to them. He says he's never seen one that couldn't be turned by hand with the brake full on. He didn't think it was worth the investment for a trailer as light as ours. I agreed, but I ordered the K-flange anyway so that brakes can be added at a later time if we change our mind. I think it would help with resale also if a prospective buyer had the option of adding brakes.

I had no idea how dramatic the difference was between 12" wheels and 14".

Once we got it home though we were off to meet friends for an afternoon at the gun range, so teardrop stuff had to wait until today.

I only had one day to work on the teardrop this weekend, and with the days being so short, it seems that progress is coming very slowly, but here's the update.

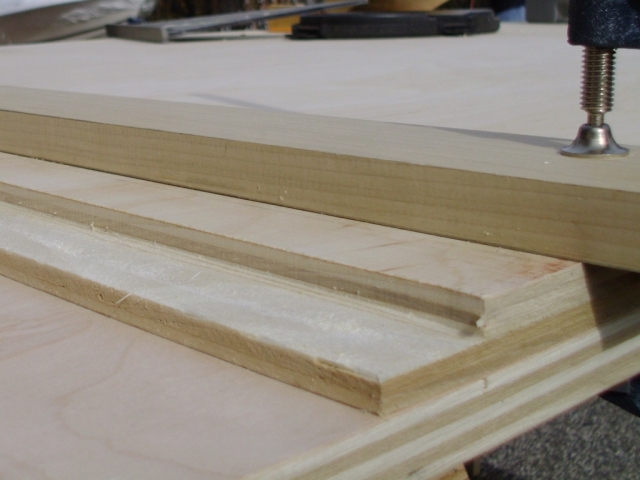

The first 30 minutes is always spent moving everything out of the garage, setting up sawhorses, putting down drop cloths, getting the tools out, etc. etc. All my "parts" at this point (floor, 10' solid 3/4" plywood walls) are too heavy for me to lift alone. Poor Lance has trouble getting his own projects done when I am working on the teardrop because I am constantly asking him to help me move something in or out of the garage. I will be so happy when the walls are up. I will be able to handle all the pieces on my own after that.

Once I got set up the first order of business was to wash the amine blush off the bottom of the floor.

While that was drying, Lance and I dropped the old axle off of the frame so he could install the new axle and wheels and tires for me.

He had to drill 2 new holes for the top mount for the axle, but other than that everything fit perfectly and it went on without any problems. He is always there to help me with the hard stuff.

The angle of this photo is a little screwy, but the trailer sits perfectly level behind the Jeep now. At least it appears that way to my eye.

While the floor was drying and Lance was drilling new holes for the axle mount, I got the router out and made the lap joints for one of my side walls. I am just horrible with a router. I do a fair to midland job with most other tools, but not the router. I did the joints on one wall last weekend. I took off too much and had to fill the gap with thickened epoxy. This week the cuts were better, but not perfect. Still have a little bit of a gap. A little bit more thickened epoxy and all will be right with the world.

The last task for today is coating the road side of the floor with black asphalt emulsion. I used Henry's. It's found in the roofing materials section of any big box hardware store.

First I taped off the edges of the floor because they are going to be bonded to the tops of the 2x4's that will run along the sides of the frame. You guys call this stuff "evil black goo" for a reason. What an unholy mess.

I also coated 2 sides of the 2x4's, the side that faces the frame and the bottom side that faces the road. The top side will be bonded to the floor and the outside will be bonded to the walls.

The bottom of the floor is now done. It looks great and after curing good this week it will be ready to install permanently onto the trailer next weekend.

Another 30+ minutes putting everything back into the garage and I am done for the day.

Have a great week!!

Becky

http://www.teartime.com

http://www.teartime.com