Thanks everyone for the replies,

Napping is one of my favorite hobbies so it is important that our trailer have the most comfortable sleeping quarters possible.

There is more to update:

Okay here is part 4 :

After working on the awnings my hubby and I spent the day installing the hardware on the drawers in the base cabinets of the galley.

We started with the drawer slides . I followed the directions I found on you tube at :

http://www.youtube.com/watch?v=0E7SqMQSxGg&feature=relatedThe slides are all stainless steel. The oven drawer is able to hold 75lbs.

All the slide were installed, thankfully they all fit.

This isn’t the most flattering image of my hubby. He kept making weird faces while I was taking the pictures.

Oven drawer detail

Then we attached the drawer fronts, the hardware is also stainless. We chose as much corrosion resistant fittings as possible as we plan on doing beach time.

The empty space is where the refrigerator will fit.

Then we attached the hinges and catches to the electrical and water access drawers.

The next step was to work on the hatch. So I traced the shape of the hatch curve onto ¾ inch plywood added 1 ½ inch thickness and cut it out with the saber saw . Then I traced out 7 more. And my hubby rough cut them.

Then I routed them to match the master spar. My better half was absent for this part because he had to take my 16 year old son for driving lessons. I think he had the worse of the two jobs, using a tool that can shred the flesh off your bones is far less scary than driving with a teen.

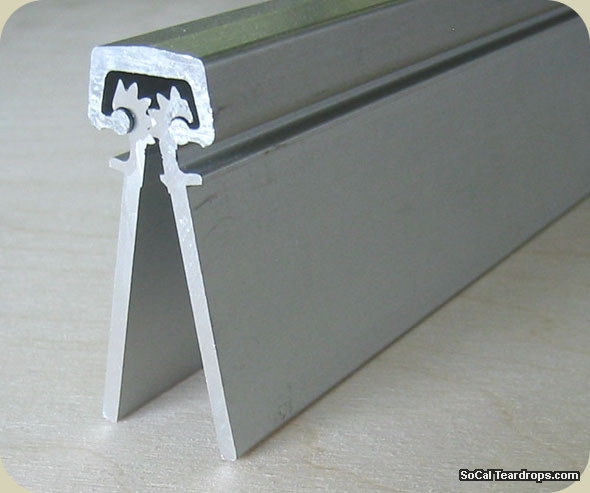

When he returned we cut the hinge to size. We are using the hinge available from So-cal .

Their directions were very good. We attached the hinge to the trailer side of the galley, so we could fit the cross pieces. Then we assembled the spars to the top and bottom with pocket joints reinforced with triangular blocks.

Detail of upper side. Showing double thickness of oak to we used to provide adequate strength to attach hinge.

That was as much as we were able to accomplish that weekend. This weekend we were back on hatch detail. We started by adding cross pieces to strengthen the spars and to provide places to attach edges of the outer skin. At this point I realized I could have just made the hatch 5 foot long and saved ourselves aggravation. Oh well… maybe next build.

The next step was to sand the hatch skeleton smooth. Then we installed the hatch. We decided that we wanted the T-handled latch workings hidden in the hatch. However at 1/½ inches thick there wasn’t enough room to do that easily. So I cut apiece of oak to fit between the spars and routed out an area to inset the mechanism. The mechanism was bolted to this on the inside and then the whole thing was attached to the spars.

Inside view of latch panel. The drywall screws will be replaced with decorative screws when I remember to get them.

Then holes were drilled to allow the rods to pass. The rods were attached with cotter pins and then cut to length, flush to the sides when the mechanism was set to open.

After the latch was done, we noted the measurements for the location of the t-handle spindle that will need to be drilled later. Then we applied the first layer of Baltic birch . Applying liquid nails to the spars and then clamping and stapling it down.

Tomorrow we will put down the second layer.

On another note, we received word from the trailer people that there will be another delay before we can pick up our chassis. Needless to say I became extremely miffed ( I’m sure their ears were burning).

It wouldn’t be so bad except we placed the order in September, in November they said they were starting and it would only take a few weeks, come January we still had no word. When we contacted them they said they needed a little more time and that it would be done the second week of February, when we called to confirm the pick-up date they said they needed one more week, another week and a half passed and then we received the latest e-mail that the trailer won’t be done until March 14th. I threw a hissy fit and we sent them an e-mail saying we need the trailer in no more then one more week or we want our money back. They e-mailed back ( it’s been hard to contact them by phone) saying that they would be done by next weekend. All in all it has been very frustrating. I realize this is a custom build, but it seems that a company that advertises itself as a custom fabrication shop could do it in a timely manner without lying to their customers.

Sorry for the rant...

It’s just that if don’t get this trailer body mounted soon there will be no way we will be done in time for our spring trips. It’s enough to make a person want to march up there and kick rear. ..Is tear-droppers disease a defense you can use in court?

I really do try to be the live and let live type of person, but sometimes I have a hard time of keeping my inner bad*** under control.

My inner self is exactly like this but chubbier and more sarcastic, and I don‘t care if the world ends.

Anyways thanks for viewing.

“I became insane, with long intervals of horrible sanity.”

― Edgar Allan Poe

Later y’all

Dr. C-Dawg

Thanks for all the detail. It will definitely help others in their quests for ideas and ways to make the extras they may want.

Thanks for all the detail. It will definitely help others in their quests for ideas and ways to make the extras they may want.

It wouldn’t be so bad except we placed the order in September, in November they said they were starting and it would only take a few weeks, come January we still had no word. When we contacted them they said they needed a little more time and that it would be done the second week of February, when we called to confirm the pick-up date they said they needed one more week, another week and a half passed and then we received the latest e-mail that the trailer won’t be done until March 14th. I threw a hissy fit and we sent them an e-mail saying we need the trailer in no more then one more week or we want our money back. They e-mailed back ( it’s been hard to contact them by phone) saying that they would be done by next weekend. All in all it has been very frustrating. I realize this is a custom build, but it seems that a company that advertises itself as a custom fabrication shop could do it in a timely manner without lying to their customers.

It wouldn’t be so bad except we placed the order in September, in November they said they were starting and it would only take a few weeks, come January we still had no word. When we contacted them they said they needed a little more time and that it would be done the second week of February, when we called to confirm the pick-up date they said they needed one more week, another week and a half passed and then we received the latest e-mail that the trailer won’t be done until March 14th. I threw a hissy fit and we sent them an e-mail saying we need the trailer in no more then one more week or we want our money back. They e-mailed back ( it’s been hard to contact them by phone) saying that they would be done by next weekend. All in all it has been very frustrating. I realize this is a custom build, but it seems that a company that advertises itself as a custom fabrication shop could do it in a timely manner without lying to their customers.

It’s just that if don’t get this trailer body mounted soon there will be no way we will be done in time for our spring trips. It’s enough to make a person want to march up there and kick rear. ..Is tear-droppers disease a defense you can use in court?

It’s just that if don’t get this trailer body mounted soon there will be no way we will be done in time for our spring trips. It’s enough to make a person want to march up there and kick rear. ..Is tear-droppers disease a defense you can use in court?

And yes my husband is very lucky, because he won't have to hear me whining about this any longer.

And yes my husband is very lucky, because he won't have to hear me whining about this any longer.

Yum!!!

Yum!!!