Today I spent a couple of hours cleaning up and fixing the factory wiring. I also got most of my rough-in wiring run started and should have that finished tomorrow am. I will also go pick up the insulation tomorrow and start on that. If all goes well, my plan is to have trailer somewhat usable for the May long weekend which is 8 weeks away...

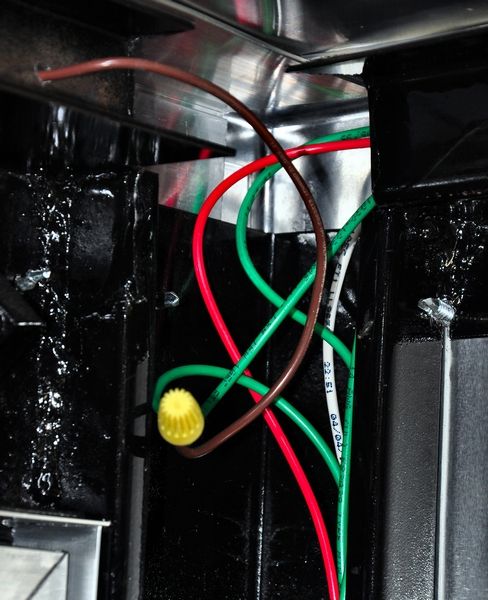

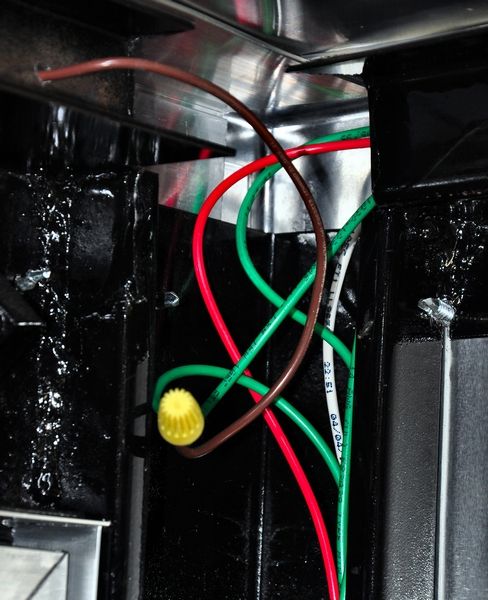

The factory wiring in this trailer and many others I looked at while researching before purchasing, leaves room for improvement. The main wiring loom here at the front of trailer is a good (bad example). As you can see, the wiring is being pulled against and down from the small section of steel channel which would of rubbed a hole through the wiring in a very short time.

I relocated the wiring away from the channel, separated it and also fixed up the wire loom so that wires in there are better protected. As you can see, I still need to wire wheel out the surface rust and spray with some Tremclad Rust paint.

This run of wire did not have a grommet and it would of been a work to pull the wire. I used a short length of clear tube in which 14 gauge wire fits perfectly to help protect against any rubbing from the steel which I checked and there are no sharp edges etc on it.

The wiring in both back corners of trailer were also in need of attention. Notice the brown wire and where it exits that sharp edged hole? I pulled the wire out and re-routed it in behind the steel channel.

I took the Dremel to the steel channel edges but I was not completely confident that this alone was enough so I disassembled all the wiring connections then again, used clear tubing to further protect the wires.

Wire run in the back corners where the lights are.

Before

After:

My dilemma of running wires through all the wall studs have been solved. I noticed today that the roof supports taper down and away from the roof as they junction at the side walls. I surmise that with this trailer being flat roofed, they use the same roof supports for the rounded edge roofs which would explain the gap there which is perfect for the wiring. The photo looks a bit deceiving as the gap is enough that I can put my index finger in it. I also used the Dremel to ensure there were no sharp edges on any of the supports. Tomorrow, the wires will get a few wraps of thick insulating tape which will ensure that there will be no way for the wires to be rubbed through, especially this wire that is already encased as it is.

Another issue. That protruding screw is very close to the wire and I don't like not knowing the condition of the wire under that poor tape job...

I also removed, inspected then re-wrapped the wiring here as I did on all other wires today. At this point, I am much more confident knowing that the factory interior wiring is now all inspected and fixed where needed.

I have the same kinds of issues with mine and will be tackling the fixes later this week.

I have the same kinds of issues with mine and will be tackling the fixes later this week.

I have not noticed any water getting into the lights and I did check for leaks pretty well after the first couple of major rains. You see all that water sheeting over the windows and you just know something is going to leak somewhere lol. So far so good..

I have not noticed any water getting into the lights and I did check for leaks pretty well after the first couple of major rains. You see all that water sheeting over the windows and you just know something is going to leak somewhere lol. So far so good..