So pleasure boating is just like camping except you do it on the water, right?

And we all like the creative build process and ingenuity that goes into a custom creation or “resto-mod” (modified restoration), right?

And the recuperative process, you know, recovering from working so hard, is part of the build, too, right?

And this is my build thread so it’s okay if I go off topic from time to time, right?

So that’s my justification for this little OT photo diary of our recent boat trip.

(If you would prefer to just see trailer build progress scan down.)

Sunday morning we (Chris and Karl, and Yvette and me) packed our day bags and a picnic lunch (thanks to Chris) and went down to a local marina in New London to meet Tina and Dale on their boat.

She’s a Sea Ray 340 Sundancer that Dale has been restoring over the last couple of seasons. Twin big block Chevy based Mercury Marine 8.1L V8 inboards.

They had been out at Montauk Point Long Island NY at a gathering of like minded Sea Ray forum members, and made the trip over to pick us up, refuel, and pump sanitary tanks.

Here’s “Captain” Dale and “First Mate” Tina, while we were sitting waiting for the train bridge to turn and let us out of the marina.

Here’s a shot of part of the dinghy mount that Dale designed, fabricated and installed (more in his blog,

http://www.searay340restoration.blogspot.com/).

And the 2.5 HP propane fueled outboard that uses the same fuel cans as our camp stoves and lanterns… pretty nifty!

Pic of a deep sea research vessel with mini sub and USCG tug (far side).

General Dynamics Electric Boat Division shipyard. This is where most of the nuclear powered US Navy submarines have been built. The big green building is the hull assembly area. I worked there for 13 years and my office was in the big shiny silver building up on the hill (just to the left of the yellow bridge crane). From my office on the 9th floor I could look out and see the traffic coming and going on the river. It was a nice perk.

The attack class dry docks are down in front in between the cranes.

Pfizer’s home base is just down the river from EB.

Blurry pic of New London Harbor Light.

Karl and Chris as we leave New London.

Takes a lot of fuel to feed those powerful big blocks and push this much water around. The boat weighs about 18k lbs. IIRC.

Ledge Light at the mouth of the Thames River (rhymes with “flames”, not Tim’s).

We’re heading straight across Long Island Sound, over there…

Bye bye New London.

The Race

The Race was very active with birds and fisherman, as it usually is. This is where the current is always strong and choppy because of the choke point at the tip of Long Island. The tide action squirts through the relatively narrow gap between CT and LI (no pic).

Gardiner Point, a funky looking rock outcropping.

This is either Plum Island or Orient Point.

This is either Plum Island or Orient Point.

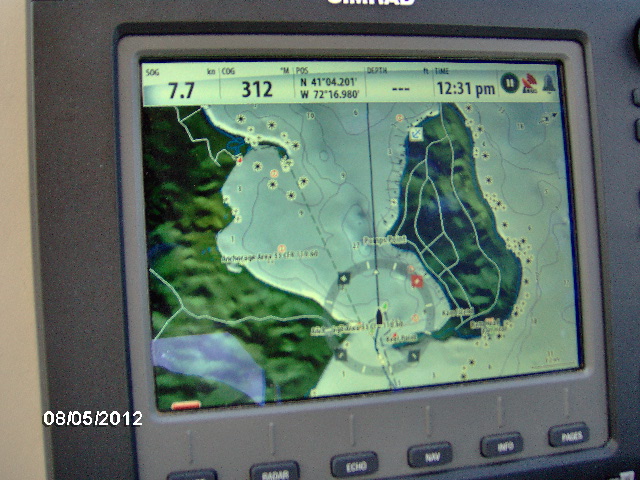

Here we are approaching the narrow inlet to Coecle's Harbor on Shelter Island. The channel is very narrow between two sprits of sand. The GPS chart plotter showed 1 foot draft to port of the channel, depth finder went down to about 7 ft on a 3 ft draft.

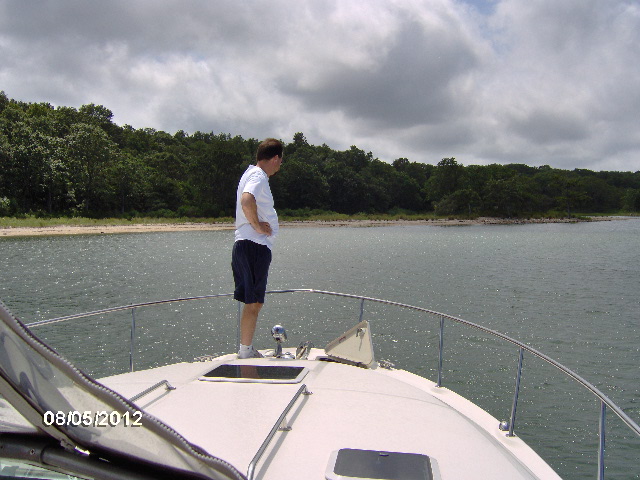

Here’s Dale setting anchor in the public mooring area using the powered windlass.

We enjoyed a nice refreshing dip in the cool salt water, the pleasant views all around and breaking into our picnic lunch while catching up with friends.

Dinghy rides ensued.

Sorry, no pics of the return ride. I had my hands full steering the boat! At least part way. The channel back through the inlet was fun and not as much of a challenge as I thought it might be. The following wind gave me a bit more trouble splashing about and dowsing everyone and everything with sea spray. Dale changed course and throttle settings, running with the wake and through The Sluiceway to avoid The Race on the way back.

30 gph for a total of about 3 hrs cruising under power at $4.46/gal of marine gas; you do the math. (Hint: about $400 worth of fun.) Time spent with your best friends; priceless! Thanks Tina and Dale for the treat, and thank you Dale for building such a fine and safe boat.

Monday evening I pulled the curbside wall out from its bondage and trimmed the GG squeeze out.

I almost got this part all in one piece.

This one was a little rougher than the street side, but I got the outside to where I was happy with it, and most of the inside, too, before calling it quits.

Tuesday night the door latches had arrived, but I forgot to bring them on Wednesday in the mad dash out to work, so I “had to” swing by the house to get them and got a late start at Mecca last night.

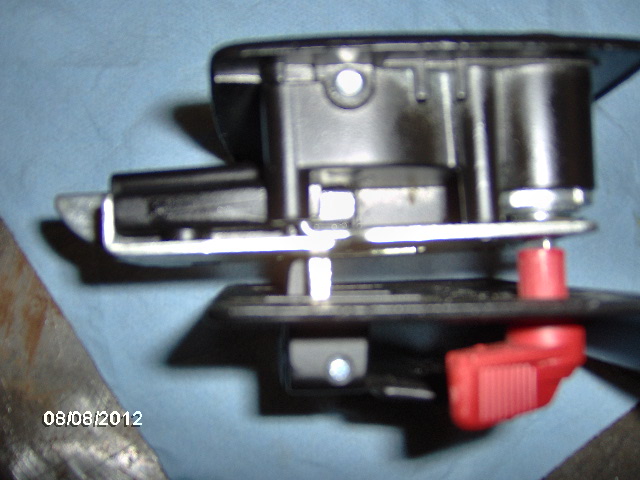

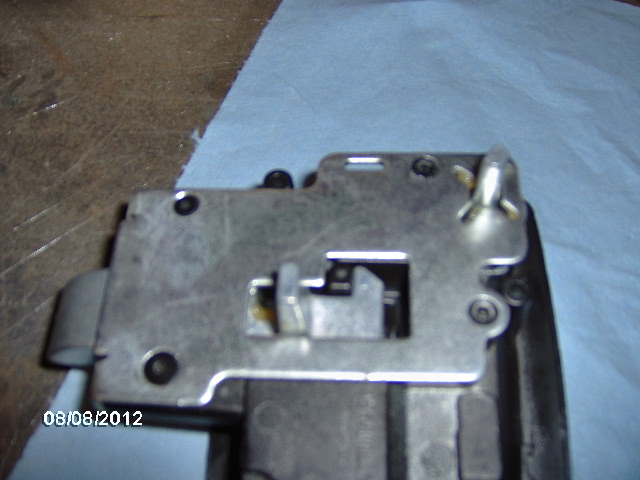

Here are some pic’s of the latches. They are TriMark Item #20907-01-K, Kit (29792-01) for doors 1-3/4 thick plus.

They are all four keyed alike (both latches and dead bolts) by special request (thank you Steph).

Here is the trim plate that gets installed around the bolt mortise.

It is very thin plated steel. I may consider an upgrade and make stainless steel replacements later.

The differences between the standard latch and the thick door latch appear to be in the locking lever shaft and perhaps one or both of the tabs where the lever on the back of the inside pull paddle reaches through to the retract tab on the inner portion of the bolt (the gray and shiny silver blobs in between the inner plate and latch shown in this blurry pic).

Here’s a better pic of the bolt retract tab.

And the inner paddle tab.

Maybe getting ahead of myself, but I decided to make a router template based on the spec’s that I had down loaded for the latch cutouts. First I needed to trim the rough edge of the drop piece of luan that came from the window recessing template.

Did a little layout to allow for the opening and an alignment cleat, and cut the opening.

Test fit found a bit of slop, but I assume this is intentional to allow for some wiggle room and adjustment. I may do a full scale mockup of the door latch area and do a test cut/fit using the template before I commit to cutting the real doors. Too much time invested in them at this point.

Glued and screwed the cleat that will be used to align the template to the edge of the door.

Then I finished by trimming some of the excess material away from the edges of the template (no pic). Only a couple of hours work, but Karl and I spent some time talking about next gen chunker design.

That’s going to do it for me for a couple of weeks while the wife and I enjoy a much deserved and long awaited vacation. I may get to look in on the forum, and may even post a bit here and there, but the build will be on hiatus until the last week in August.

I intend to jump right back in hot and heavy so that I make it to Poet Creek (crick) next season, come hell or high water!

Thanks for looking in.

.

.

The PCE looks like it's coming along quite nicely.

The PCE looks like it's coming along quite nicely.The PCE looks like it's coming along quite nicely.

(tee-hee)

(tee-hee)