Nano Cub

35 posts

• Page 2 of 3 • 1, 2, 3

-

Micro469 - Super Lifetime Member

- Posts: 3185

- Images: 382

- Joined: Mon Nov 07, 2005 10:46 pm

- Location: Brampton,Ontario,Canada

Re: Nano Cub

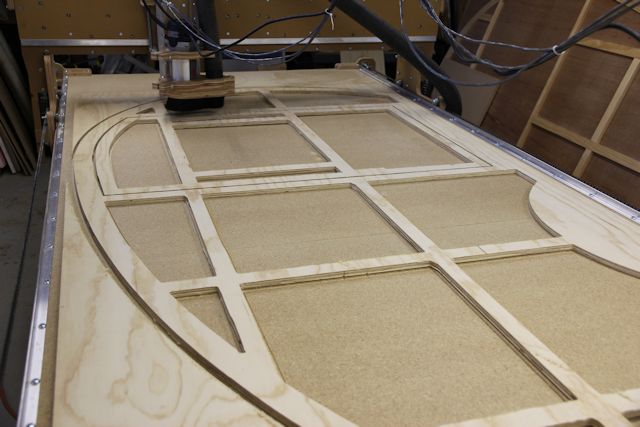

mikeschn wrote:Micro469 wrote:I presume that's a 4x8 piece of plywood. What thickness is it....and how much does it weigh? and after you routed it out.....what's the final weight??

John,

Yes, it's a 4x8 1/2" plywood. I"ll run down and check the weight in a bit.

Thinking about another one are you?

Mike...

How long is "a bit" ?

John

-

Micro469 - Super Lifetime Member

- Posts: 3185

- Images: 382

- Joined: Mon Nov 07, 2005 10:46 pm

- Location: Brampton,Ontario,Canada